-3

-

2.3 Arc Welding Sequence

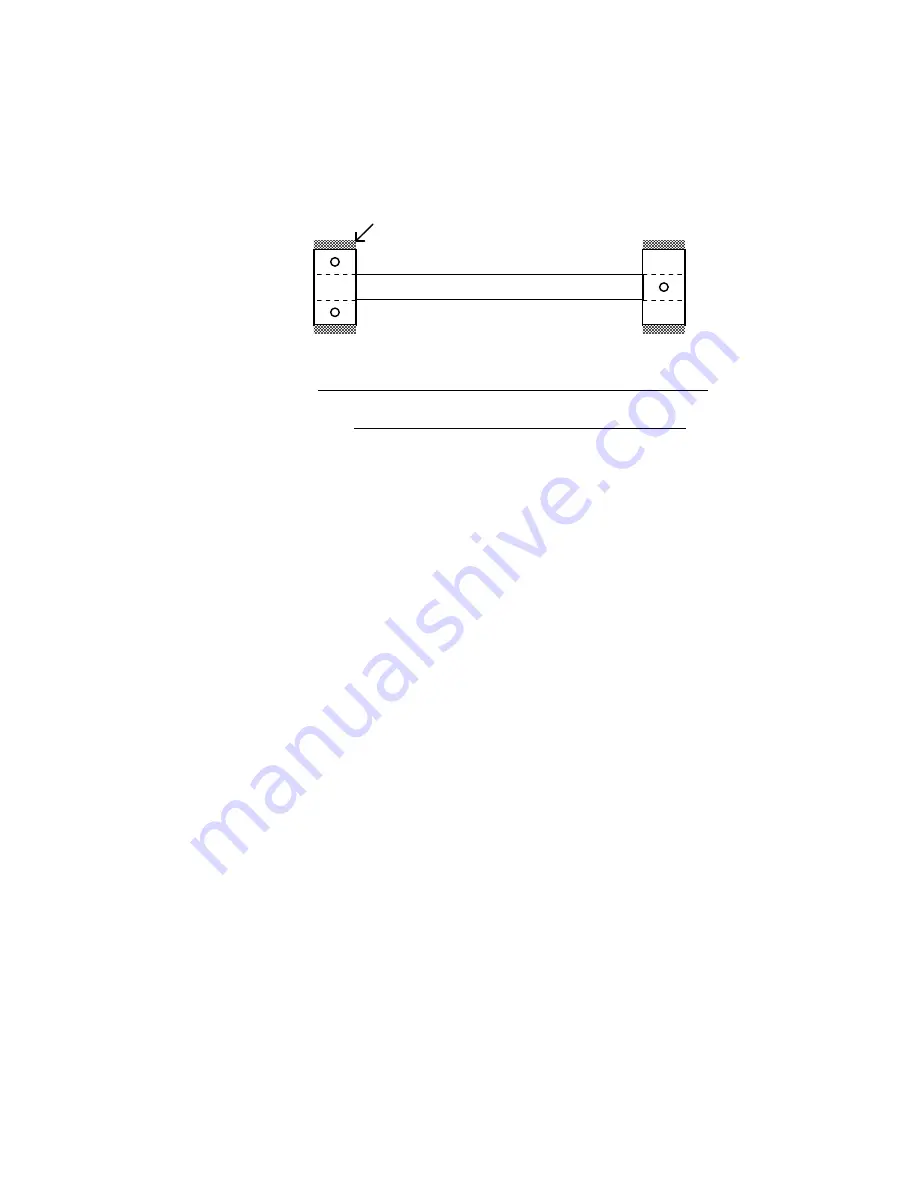

The steel surface is cleaned using a wire brush to remove all scale, rust, dirt and oil. The

blocks are then removed from the spacing jig and pressed firmly against the steel surface

using the spacer bar as a handle. The edges of the mounting blocks are now welded in the

order as shown in Figure 3.

1

3

4

2

SPACER BAR

WELD

Figure 3 - Welding Sequence for the Mounting Blocks

Avoid excessive heat and DO NOT WELD THE FLAT END SURFACES as this will prevent

removal of the spacer bar. Avoid welding splatter which could stick to the spacer bar.

To

speed things up, where many gages are being installed, it is advantageous to have

more than one spacer bar.

After welding, cool the mounting blocks with a water-soaked rag, then slacken the set

screws and slide out the spacer bar. Clean away all welding slag using a chipping hammer

and wire brush. (Optional: Paint over the surface to provide some protection against

corrosion).

2.4 Setting the Strain Gage

When the mounting blocks have been welded in place the strain gage can be slid into the

holes in the mounting blocks. One end of the strain gage has a V-groove in it - make sure

that this end goes inside the mounting block that has the single cone-point set screw.

Tighten hard the cone point set screw into the V-groove. Now clip the coil housing around

the gage and connect to the readout box (

Channel C

). Set the initial reading on the gage to

the correct level depending on whether compressive or tensile strains are anticipated. The

useable range of the strain gage runs from around 1000 to 4000 microstrains. The mid-

range reading is 2500. The reading can be adjusted by simply pulling or pushing on the free

end of the strain gage. Strain gages are shipped with a reading of around 3000 to 3500.

This level is OK for compressive strains. If tensile strains are to be measured set the initial

reading to around 1500.

When the desired reading has been achieved tighten the two cone-point set screws in the

mounting block: tighten hard down onto the end of the strain gage. Tighten the hose clamp

onto the coil housing: tighten hard using a nut driver.

Finish off by tapping the mounting

blocks with, say, the handle of a screwdriver, to remove any installation strains and

stabilize the initial reading. Tap until the reading remains stable