6

ENGLISH

LEDS

1

- Stop

2

- Pulse A

3

- Pulse B

4

- Photocells

5

- Opening limit switch

6

- Closing limit switch

ON

OFF

Control deactivated

Safety devices disabled

Limit switch free

LED 7

Diagnostic

Slow:

Correct operation

Fast:

Electronic clutch circuit malfunction

or incorrect motor connection

Control activated

Control activated

Limit switch free

Control activated

Control deactivated

Control deactivated

Safety devices enabled

Limit switch occupied

Limit switch occupied

5.2 STOP

Terminals “11-12” (Circuit Normally Closed). The status of this input is signalled by

LED 1

. This circuit is connected to any device

(e.g. button, pressure switch) which, when a contact is opened, can stop the gate motion.

Note

: If STOP devices are not connected, jumper connect the input. To install multiple STOP devices, connect the NC

contacts in series.

5.3 PULSE A - TOTAL OPENING

Terminals “11-13”. (Circuit Normally Open). The status of this input is signalled by

LED 2

. This circuit is connected to any device

(e.g. button, radio control, etc.) which, when a contact is closed, generates a gate opening and/or closing pulse.

Note

: To install multiple pulse devices connect the contacts in parallel.

5.4 PULSE B - PARTIAL OPENING

Terminals “11-14”. (Circuit Normally Open). The status of this input is signalled by

LED 3

. This circuit is connected to any device

(e.g. button, radio control, etc.) which, when a contact is closed, generates a gate opening and/or closing pulse. The

opening time has a fixed lenght of 10 seconds.

Note

: To install multiple pulse devices connect the contacts in parallel.

5.5 CLOSING PROTECTION PHOTOCELLS

Terminals “15-16” (Circuit Normally Closed). The status of this input is signalled by

LED 4

. This circuit is connected to any safety

device (photocells, pressure switch, detector, etc.) which, when a contact is opened, acts as a safety on the closing motion.

The effect will vary depending on the settings performed using dip-sw 4.

Note

: To install multiple safety devices connect the NC contacts in series.

Note:

If safety devices are not connected, jump connect the input.

It is possible to prevent the gate from closing by connecting a 24h timer in series to the closing photocell circuit.

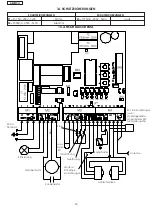

6. TERMINAL BOARD M4 (LOW VOLTAGE) CONNECTIONS - DESCRIPTION

6.1 OPENING LIMIT SWITCH

Terminals “17-18” (Circuit Normally Closed). The status of this input is signalled by

LED 5

. This circuit is connected to the

opening limit switch.

6.2 CLOSING LIMIT SWITCH

Terminals “18-19” (Circuit Normally Closed). The status of this input is signalled by

LED 6

. This circuit is connected to the closing

limit switch.

6.3 ACCESSORY POWER SUPPLY

Terminals “20-21”. (24 V~).

Warning

:

the max. load for the accessories is 500 mA.

6.4 ANTENNA

Terminals “22-23”. Antenna input. This should not be used if the receiver already has its own antenna input

7. INSERTING THE REMOTE CONTROL RECEIVER BOARD

The unit is designed to house a single or two-channel radio-receiver module. To install the module, cut off the electric power

supply and insert the module into the special connector

M5

inside the unit.

8. TWO-CHANNEL SELECTION JUMPER

When a two-channel radio-receiver module is inserted into connector M5, it is possible, using jumpers

JP1-JP2

, to activate

or deactivate the second channel on pulse B (partial opening): jumpers enabled = second channel activated; jumpers

disabled = second channel not activated.

9. CONTROL LEDS

Note: Bold is used to indicate the led condition with the gate at rest.

10. ADJUSTMENTS WITH TRIMMER

10.1 ELECTRONIC CLUTCH

To adjust the anti-crushing system tripping threshold use trimmer “

A

”. To reduce the torque, turn the trimmer counterclockwise.

To increase the torque, turn the trimmer clockwise. It is recommend to calibrate this torque to meet current standards.

10.2 PAUSE

To adjust the pause duration (for automatic operation), use trimmer “

B

”. The duration can be adjusted from 0 to120 seconds.

10.3 OPEN/CLOSE

To adjust the duration of the gate opening/closing time, use trimmer “

C

”. The duration can be adjusted from 10 to 120

seconds.

Note

: To obtain maximum system efficiency, adjust the opening/closing time so that the electric motor can be fed

for a few seconds after the gate has reached the limit switch.