4.0 Operation

4.1

Calibration

Activating the Calibration Switch will auto-

matically disable the alarm circuits by sending

a 1.5mA (0mA optional) output signal. This

will prevent activation of the relay contacts

when using a General Monitors Readout/Re-

lay Display Module with the Model S104.

General Monitors recommends that the Model

S104 Combustible Gas Enhanced Smart Sen-

sor be calibrated one hour after start-up, and

that calibration be checked at least every

ninety (90) days to ensure system integrity.

General Monitors is not implying that the cus-

tomer should expect problems with sensor life

or stability but “frequent” calibration checks

merely ensure the integrity of the life protect-

ing equipment.

The above statement is not intended to dis-

courage the customer from checking calibra-

tion more frequently.

Frequent calibration

checks are recommended for environments

that have problems such as mud collecting on

the sensor head, sensors accidentally being

painted over, etc.

NOTE: A calibration check consists of ap-

plying a known concentration of gas to the

sensor and observing the reading on the

Model S104, the Readout/Relay Module, or

other computer data collecting systems.

General Monitors recommends that a calibra-

tion schedule be established and followed. A

log book should also be kept showing calibra-

tion dates and dates of sensor replacement.

Procedure with digital display:

l

If it is suspected that combustible gas is

present, it will be necessary to purge the

sensor environment with Zero Air. If

Zero Air is not available, cover the sensor

for about thirty seconds before applying

the calibration gas. Zero Air is air that is

hydrocarbon free.

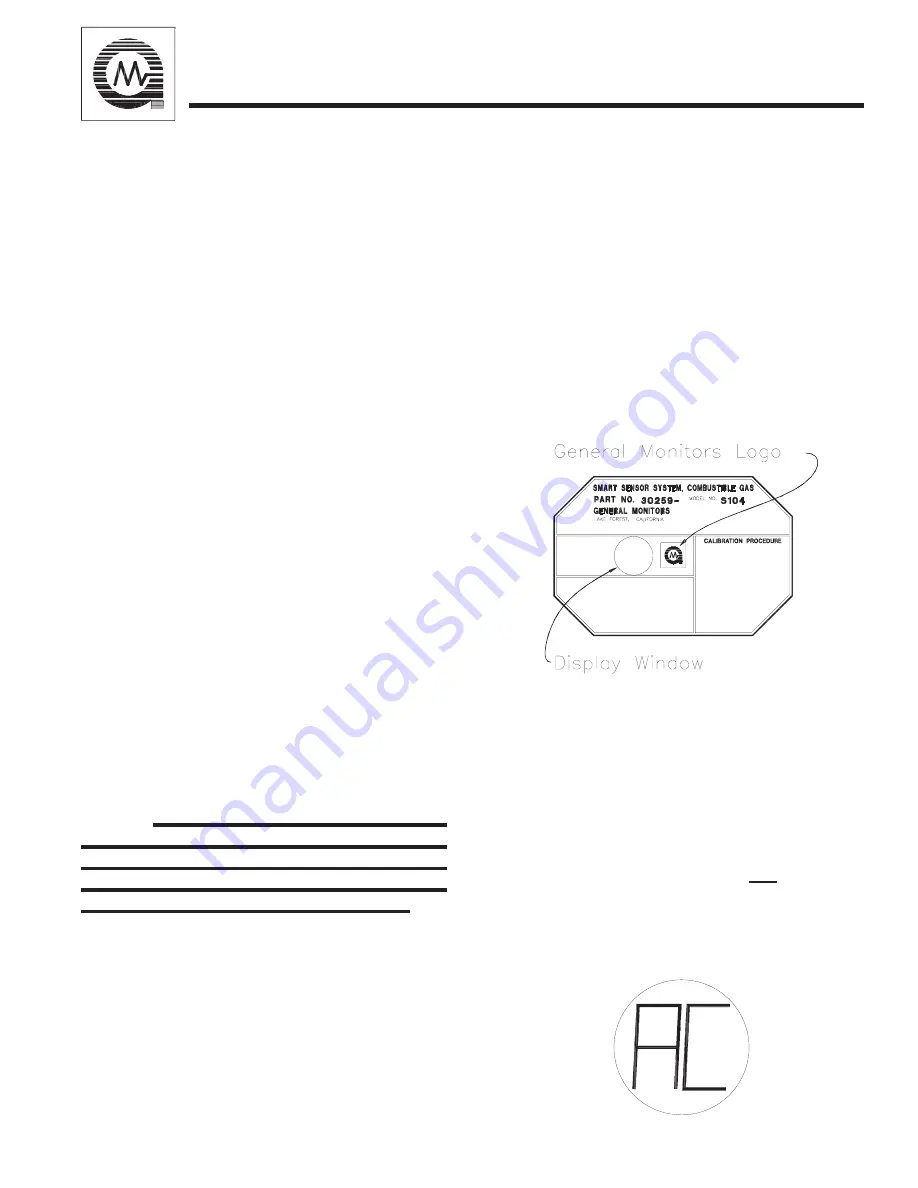

figure 12

l

Place the magnet over the GMI Logo on

the cover (figure 12) of the unit and hold it

there until “AC” (figure 13) appears on

the display (about ten seconds). Allow

about five seconds for the unit to acquire

the zero reading before applying the

calibration gas. If the GMI Portable Purge

Calibrator (P/N 1400150) is not used

when calibrating the Model S104 with

Methane (CH

4

), the SPAN gas flow rate

needs to be 440cc/min to 460cc/min. See

Appendix, section 5.4.

11

figure 13

GENERAL MONITORS

Model S104