17

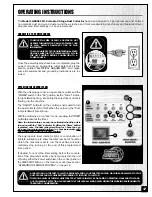

CONNECTING TO A POWER SOURCE

OPERATING INSTRUCTIONS

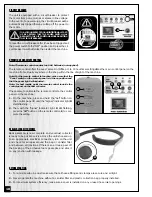

OPERATING THE CONTROL PANEL

With the unit plugged into an appropriate outlet and the

“POWER” switch in the “On” position,

A

, the “Power” indica-

tor light

B

will light up, indicating that electrical current is

flowing into the machine.

The “ON/OFF” button

C

on the control panel is used to turn

the dust collector ON or OFF. When the unit is on, the “Run”

indicator

D

will also light up.

With the unit turned on in “Run” mode, pressing the “TIMER”

button

E

activates the timer.

Note: the timer feature can only be activated when the unit is

turned on with the “Run” indicator lit. When the “Timer” button

is pressed once, the dust collector will run for 1 hour. You can

increase the programmed run time, in 1 hour increments, with

each successive push on the timer button.

The appropriate timer indicator light, or combination of

lights,

F

, will light up to show the total number of hours for

which the machine is set to run. The machine will auto-

matically stop running at the end of this programmed

time period.

If desired, to cancel the timer setting before the comple-

tion of the programmed time period, simply turn the unit

off, using either the Power switch

A

on the control panel or

the START/STOP button on the remote control (see section

“OPERATING THE REMOTE CONTROL”, on page 18.

A

F

C

ALWAYS TURN ON THE DUST COLLECTOR BEFORE STARTING YOUR DUST PRODUCING MACHINE AND ALWAYS STOP THE

DUST PRODUCING MACHINE BEFORE TURNING OFF THE DUST COLLECTOR.

THE SOUND LEVEL OF THIS MACHINE IS RATED AT APPROXIMATELY 80 DB DURING OPERATION. MAKE SURE THAT ADE-

QUATE HEARING PROTECTION IS USED AND THAT THE OVERALL SOUND LEVEL WITHIN THE WORKING ENVIRONMENT IS

TAKEN INTO CONSIDERATION.

D

E

B

This

Model 10-800CF M1 Portable 2 Stage Dust Collector

has been designed to capture remove and collect

non-metallic dust and wood dust around the workshop and from woodworking machinery and features 15 pre-

programmed timer settings in 1 hour increments.

TO REDUCE THE RISK OF SHOCK OR FIRE DO NOT

OPERATE THE UNIT WITH A DAMAGED POWER CORD

OR PLUG. REPLACE DAMAGED CORD OR PLUG

IMMEDIATELY.

TO AVOID UNEXPECTED OR UNINTENTIONAL START-

UP, MAKE SURE THAT THE POWER SWITCH

A

IS IN

THE OFF POSITION BEFORE CONNECTING TO A

POWER SOURCE.

Once the assembly steps have been completed, plug the

power cord into an appropriate outlet. Refer back to the

section entitled “ELECTRICAL REQUIRMENTS” and make

sure all requirements and grounding instructions are fol-

lowed.

Содержание 10-800CF M1

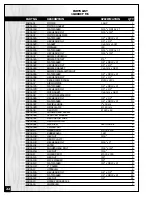

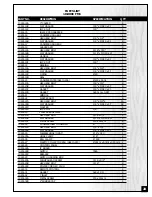

Страница 24: ...WIRING DIAGRAM 24...

Страница 25: ...25 Notes...