6

Generac

®

Power Systems, Inc.

Section 3 — Operation

PM-GC

3.2

THE OPTIONAL DISPLAY

The optional, programmable, remote display can be

mounted up to 1000 meters away from the generator.

Only one display per generator is allowed. The dis-

play has an IP65 front panel with an IP20 rating for

the rest of the housing. This means that the rear of

the panel must be protected if it is to be used outside.

Normally, it would be mounted to the face of a sealed

enclosure with the supplied screw type clamps. The

panel thickness should be <=6mm and the mount-

ing torque should be <=0.5Nm. The angle of inclina-

tion must be less than 35 degrees from vertical.

Connections to the unit can be made via a single

screened multicore cable and one 9 way D type male

connector, or, via separate signal and power connec-

tors(supplied). The second option is recommended

for distances of >75m.

The display is independently programmable and

could be customized to display different data from

the same product without altering the PM-GC soft-

ware. Currently, there are three versions of display

software, one for MPS (SC and IC), one for engine

controllers (PM-PC and PM-GC) then finally one ver-

sion for bifuelled engines.

3.2.1 CONNECTION DETAILS

The power supply should be in the range 18-30VDC

at 0.4A. This is normally supplied from the con-

troller. J1 pin 11 is Ground and pin 12 is +24VDC.

The case earth screw should be connected to an earth

point in the enclosure via a 2.5mm diameter wire.

The multicore cable should have 24AWG cores for

distances up to 75 meters. Above this, 18AWG

should be used.

3.2.2 CONTRAST ADJUSTMENT

Contrast may need to be adjusted depending on the

incident lighting conditions.

EITHER

1. Switch on the power to the unit.

2. During the initialization phase, a menu will

appear briefly. Press the CONFIG button.

3. Now use the CO and - keys to adjust

contrast.

OR

1. During normal operation, select the MAINTE-

NANCE screen and then use the co and -

buttons to adjust the contrast.

3.2.3 CALIBRATION

As the unit can be mounted at different angles, there

may be calibration required to compensate for paral-

lax errors.

EITHER

1. Switch on the power to the unit.

2. During the initialization phase, a menu will

appear briefly. Press the CONFIG button.

3. Now use the CALIBRATE button to calibrate the

screen

4. Five calibration crosses appear in succession on

the screen, touch them as they appear.

5. Once this is done, touch the screen within 30 sec-

onds at any position to "accept" the calibration. If

not completed within 30 seconds, calibration will

revert to original.

OR

1. During normal operation, select the MAINTE-

NANCE screen and then the "Calibrate

Touchscreen" button.

2. Follow steps 4 and 5 above.

3.2.4 CLEANING

As a result of normal operation the screen will

become dirty and should be cleaned with a soft cloth.

In order to prevent operating the touchscreen during

this time, select the MAINTENANCE page and choose

the "Clean Screen" option.

3.2.5 TOUCHSCREEN OPERATION

Operate the touch screen with a finger only, do not

use pens or other pointed objects.

3.2.6 FUNCTIONALITY

The display screen has been devised as a way to

examine data within the PM-GC. Changes to settings

cannot be made from this screen, this can only be

done via Genlink. Data has been divided into groups

and each group is shown as a button on the menu

screen. Touching the button will access the main

screen for the group. Some groups, such as diagnos-

tics, may also have sub screens associated with them.

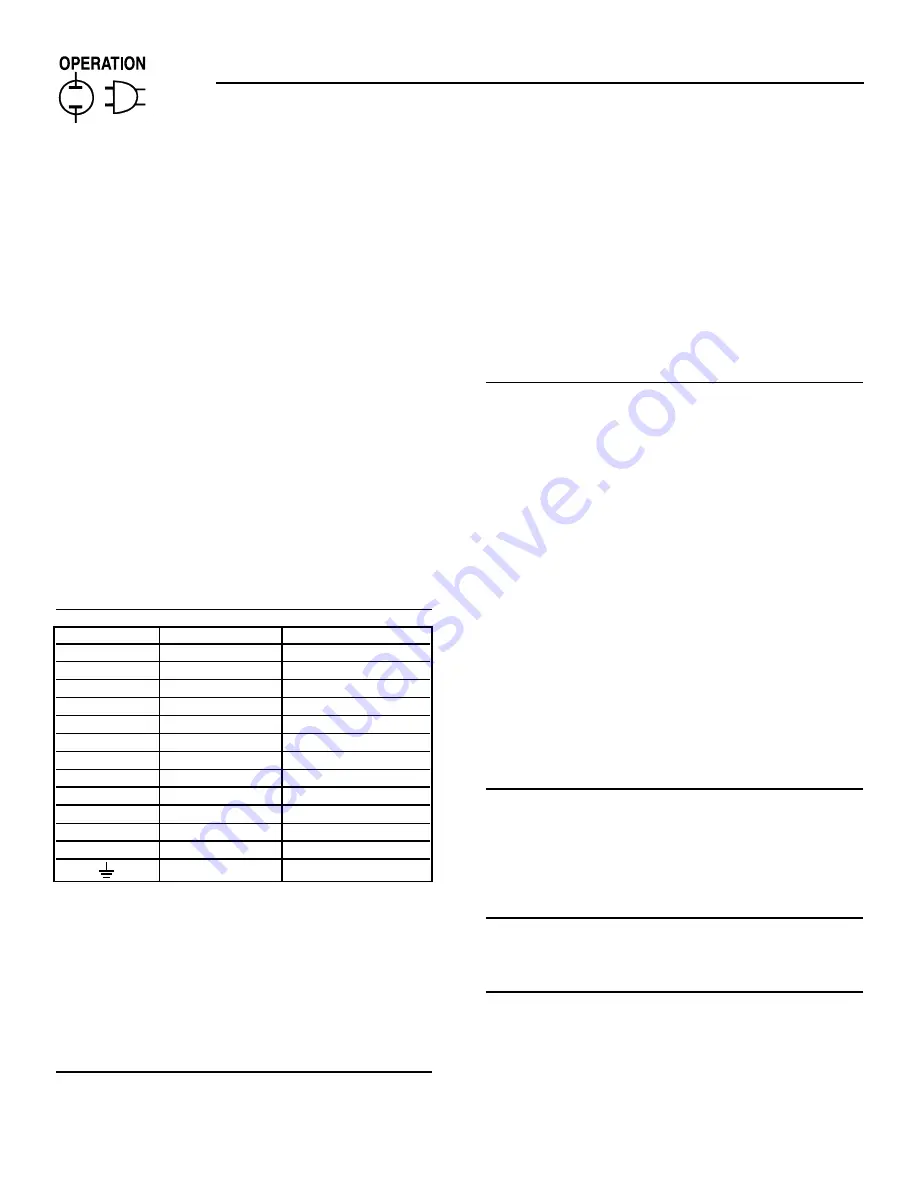

DISPLAY PIN

CONNECTION

CONTROLLER PIN

1

-

-

2

-

-

3

RS485-

J1 - 21

4

-

-

5

-

-

6

-

-

7

-

-

8

RS485+

J1 - 20

9

-

-

TERMINAL

CONNECTION

WIRE

+24VDC

24VDC

220C

OV

OVDC

0

GROUND

0