11

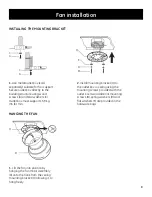

ATTACHING THE FAN BLADES

INSTALLING THE LIGHT KIT

Insert the blade (P) through the slot in the

bottom band, align the holes in the blade

(P) and the bracket, secure with the blade

screws (F) and fibre washers (G) provided.

Repeat this procedure with the other

blades (P).

Remove the 1 of 3 mounting plate screws

(W) from the bottom of motor assembly

(R) and keep it for future use. Loosen the

other 2 screws (do not remove). Place

the key holes on the mounting plate (S)

over the 2 mounting plate screws (W)

previously loosened, turn the mounting

plate (S) until it locks in place at the

narrow section of the key holes. Secure

by tightening the 2 screws previously

loosened and the one previously removed.

Remove the 1 of 3 light kit mounting

screws (X) from the mounting plate (S)

and keep it for future use. Loosen the

other 2 screws (do not remove). While

holding the LED light kit (T) under the fan

motor assembly, make the 2-pin wire

connections: -Red to red and black to

black. Place the key holes on the LED light

kit (T) over the 2 light kit mounting screws

(X) previously loosened, turn the LED light

kit (T) until it locks in place at the narrow

section of key holes. Secure by tightening

the 2 screws previously loosened and the

one previously removed.

Raise glass shade (U) up against the light

kit (T) and secure it to fan by twisting glass

(U) clockwise until snug. Do not over-

tighten.

NOTE: before starting installation,

disconnect the power by turning

off the circuit breaker or removing

the fuse at fuse box. Turning power

off using the fan switch may not be

sufficient to prevent electric shock.

F

P

G

W

S

S

X

T

T

U

Fan installation