Page 43

XI. SPECIAL EDITION ON MAINTENANCE OF ENVIRONMENTAL PROTECTION

REFRIGERATOR

11.2.2

The change of compressor oil

The original Naphten type of mineral oil

and Olefines type of synthetic oil have

now been changed to Ester oil.

i.

Vacuum treatment must be

conducted within 15 minutes after

opening the sealing plastic

membrane of compressor, dryer and

capillary tube to avoid the invasion of

water. The Ester type of oil has a

stronger water absorption power

capable of absorbing 200 ppm of

saturated moist, which is 40 times

more than the original oil.

The acid reaction will be produced for

water from the Ester oil and this type

of acid will display metallic chloride

reaction for the metal, which tends to

clog the capillary tube. Thus, special

care should be drawn to the time

duration after opening the sealed

compressor and dryer (treatment

must be conducted within 15

minutes).

ii.

The tool used for HFC-134a freon

system must be exclusive and the

new parts material must be firstly

cleaned before use. The Ester used

for HFC-134a contains 10ppm~

20ppm of solubility which is lower than

the original product (the CFC-12 for

compressor oil, joint, pressure gauge,

anti-rust oil). When mixing with the

original oil system, the residues will

be separated from the capillary tube

that has formed the cause of moist

clogging. Therefore, it is prohibited to

use the current tools (for R-12, R-22,

R50); instead, the new and special

tools for HFC-134a are used together

with HFC-134a Ester oil as well. (For

the freon container, freon filling tank,

coupling, pressure gauge, valve,

tubes, compound pressure gauge,

vacuum pump, tube cutter, fast

coupling, etc. the mixing of the original

system oil should be avoided).

In addition, the tools for the new

product must be cleaned by Alcohol.

It should be noted that even the

mixture of few grams of oil will

deteriorate the function of the freezing

system.

iii. The use of flux is prohibited for

welding:

Water may seep into the system

when the water soluble flux is used

for welding, so it is prohibited to use.

Basically, the copper tube and iron

tube welding will be avoided as much

as possible and if necessary, fresh

water will be used to dissolve it. To

prevent the fluochlorine of tap water

from getting into the freezing system,

the cleaning flux should be prevented

from seeping into the freezing

system.

Содержание PTV15SAMR

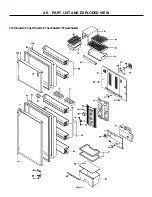

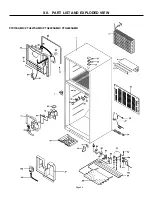

Страница 53: ...Page53 XII PART LIST AND EXPLODED VIEW PTV15SAMR PTU427SAMR PTQ440SAMR PTG440SAMR...

Страница 54: ...Page54 XII PART LIST AND EXPLODED VIEW PTV15SAMR PTU427SAMR PTQ440SAMR PTG440SAMR...

Страница 61: ...Page61 XII PART LIST AND EXPLODED VIEW PTV16SAMR PTU463SAMR PTQ470SAMR PTG470SAMR...

Страница 62: ...Page62 XII PART LIST AND EXPLODED VIEW PTV16SAMR PTU463SAMR PTQ470SAMR PTG470SAMR...

Страница 70: ...Page70 XII PART LIST AND EXPLODED VIEW PTV19SAMR PTU527SAMR PTQ530SAMR PTG530SAMR...

Страница 71: ...Page71 XII PART LIST AND EXPLODED VIEW PTV19SAMR PTU527SAMR PTQ530SAMR PTG530SAMR...

Страница 78: ...Page78 XII PART LIST AND EXPLODED VIEW PTV20SAMR PTU565SAMR PTQ570SAMR PTG570SANR...

Страница 79: ...Page79 XII PART LIST AND EXPLODED VIEW PTV20SAMR PTU565SAMR PTQ570SAMR PTG570SANR...