PREPARING FOR INSTALLATION

19

Installation Instructions

TOOLS AND PARTS NEEDED

• Large flat-blade screwdriver

• Saw

• Carpenter’s square

• Pipe wrench

• 7/16

″

open end wrench

• Gas line shut off valve

• Pipe joint sealant for use with gas connections

For flexible connection where local

codes permit:

• Flexible metal tubing (same 3/4

″

or 1/2

″

I.D. as

gas supply line)

• Flare union adapter for connection to supply line

(3/4

″

NPT x 3/4

″

I.D. or 1/2

″

NPT x 1/2

″

I.D.)

• Flare union adapter for connection to regulator

(1/2

″

NPT x 3/4

″

I.D. or 1/2

″

I.D.)

For rigid connection:

• Pipe fittings as required

PARTS LIST

• Gas cooktop base unit

• Literature pack

• 1 Surface burner assembly

• 2 Surface burner grates

• 1 Vent filter

• 1 Vent grille

• 1 Grease jar

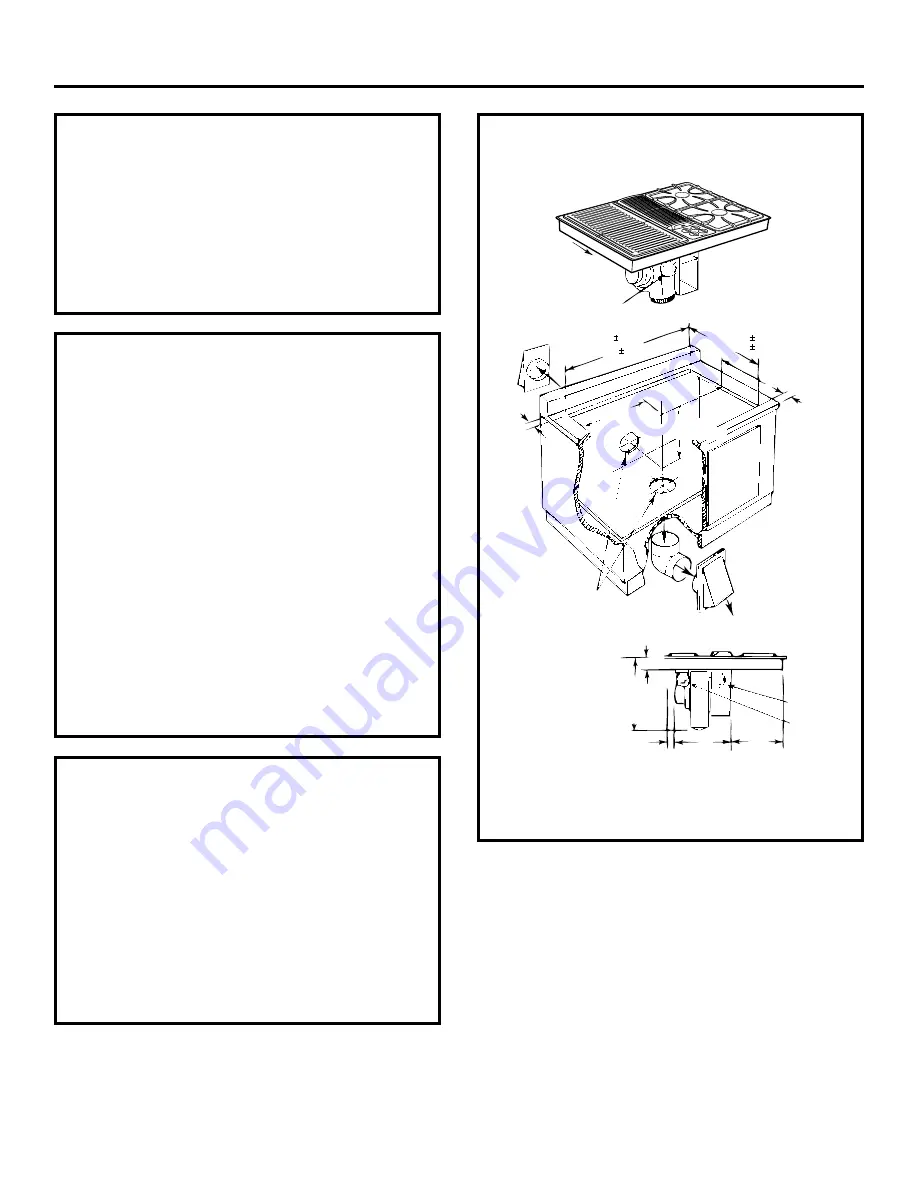

JGP979

Tie down bolt

on each end

Select appropriate

duct cutout. (See

ducting installation

instructions.)

Appliance

Pressure

Regulator

Grease

Container

Grease Container

Pressure Regulator

Wiring Box Cover

28

7

⁄

8

″

1

⁄

16

″

*Blower can be

swiveled 90°

* Blower may be rotated for horizontal or vertical direction by loosening

nuts around blower inlet. Accessible inside ventilation chamber.

7

9

⁄

16

″

15

5

⁄

8

″

3

5

⁄

16

″

11

7

⁄

8

″

9

3

⁄

8

″

1

7

⁄

8

″

Min.

15

⁄

16

″

20

15

⁄

16

″

1

⁄

16

″

Minimum

Clearance

Minimum

Clearance

73.34 .16 cm

23.81 cm

2.38 cm

8.41 cm

39.69 cm

2

″

30.16 cm

4.76 cm

19.21 cm

53.18 .16 cm

14

″

35.56 cm

13

″

33.02 cm

IMPORTANT

Motor Clearance—Provide 2

″

min. (5.1 cm) cabinet

clearance to motor for cooling purpose.

NOTE:

Where possible, 6

″

(15.2 cm) is

recommended for motor/blower service.

Side Clearance—Grills installed near a side wall

should allow a minimum clearance of 8

″

(20.3 cm).

You must allow room enough to remove and empty

grease container(s).

CAUTION:

Warranty is void on equipment installed

other than as recommended by GE. Recommended

wall caps and transitions must be used for proper

operation and installation.

5.08 cm

Minimum

Clearance