23

Installation Instructions

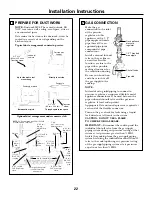

INSTALL THE DUCTWORK

• Ducting must conform to local code materials

and “make-up” requirements—300 CFM minimum.

•

IMPORTANT:

Save for local electrical

inspector’s use.

• Ducting a cooktop is easy but critical for proper

performance.

• After reading these instructions, plan the duct run.

• Use the

Duct Length Chart

on page 25 to find the

equivalent length of the run.

• Shift the blower to “high range” if indicated

(done by snapping the “restricter ring” out of

the blower inlet). Be sure blower is not running.

• Install the duct hardware.

GENERAL CONSIDERATIONS:

1.

Use 6

″

diameter round or 3

1

⁄

4

″

x 10

″

rectangular

only except as follows: For gas models, 5

″

diameter round must be used if the straight

duct length is 10 feet or less, using 5

″

round

wall cap.

2.

Do not use 5

″

elbows except in a 5

″

system.

Instead, use a 5

″

to 6

″

transition followed by a

6

″

elbow, or a 5

″

to 3

1

⁄

4

″

x 10

″

elbow transition.

IMPORTANT

Total allowance duct system is:

90 ft. with 6

″

round wall cap

80 ft. with 3

1

⁄

4

″

x 10

″

wall cap

Low range is up to 60 ft.

High range is 61 to 90 ft.

3.

Use quality metal duct of at least 26-gauge

galvanized or 24-gauge aluminum. Inferior

quality pipe and fittings can cause up to twice

the restriction shown and is a poor value. See

the

Prepare for Duct Work

section of this guide

for optional under-slab ducting. Local codes

may require a heavier gauge material or

restrict PVC.

4.

Distance between adjacent fittings (elbows,

transitions, etc.) should be at least 18

″

. The

farther the better. Closer distance promotes

turbulence which reduces airflow.

5.

The number of downstream elbows or

transitions should be limited to three. The initial

5

″

to 6

″

straight transition, if used, need not be

counted in this number.

6.

Handmade crimps are likely to cause restrictions.

7.

If an alternate wall or roof cap is used, be

certain duct size is not reduced and that there

is a backdraft damper. It is best to use listed

caps to be certain of proper performance.

8.

Thermal breaks: In areas of extreme cold

weather, it may be necessary to provide a short

length of nonmetallic duct as close to the wall

as possible to prevent conduction along the

metal duct.

9.

High altitude installations: It is advisable to

reduce allowable duct run by 20%.

10.

Follow the duct calculation in this guide carefully

for best performance and satisfaction.

PLAN THE DUCT RUN

1.

Make a sketch of the total system. Identify the

type of each fitting and the length of straight

pipe. Refer to the examples on page 24.

2.

Enter your run into the Duct Length Chart on

page 25. Elbows, wall caps and other fittings

are shown in the chart with their equivalent

straight duct length. Each fitting value must be

added to the amount of straight duct length

used to determine the overall straight duct

equivalent length. Use the following examples

as a guide.

3.

Using good quality ducting material, install per

these instructions. A few minutes and pennies

spent now will pay long term dividends for the

life of the cooktop.

SHIFTING THE BLOWER FROM

“LOW RANGE” TO “HIGH

RANGE”

This cooktop is equipped with a dual range

blower. It is shipped from the factory in low range

for most installations. If the Equivalent Duct

Length exceeds 60 feet, it must be shifted to high

range. Do not shift to high range for shorter

lengths. This will cause excessive noise,

conditioned air loss and affect the flame pattern

on gas burners.

To shift to high range,

be sure the blower is

stopped. Remove the

air grille. Remove the

filter and intake guard.

Pop the spring loaded

“restricter ring” out of

the blower inlet.

Replace the intake

guard, grille and filter.

8

9

10