24

Troubleshooting Tips

Save time and money! Review the chart on this page first and you may not need to call for service.

NO SOFT WATER – Most Common Problems:

Check the following before calling for service:

• Not enough salt—should be at least 1/3 full.

• Bypass valve in “Bypass” position—handle should be in the “OUT” (service) position.

• Hardness setting too low. Check hardness setting and adjust. Verify hardness of supply water—from

local water company, water test or call the GE Appliances Answer Center (800-952-5039 in US).

• Salt Bridge—salt solidifies above water level so that brine water is not in contact with salt. See the

Breaking a Salt Bridge section.

Problem

Possible Cause

What to do

No soft water

Faucet or fixture where sample

was taken not plumbed to soft

water. NOTE:

Be sure sample is

from a faucet that does not mix

soft and hard water. For example,

a single lever kitchen faucet, if the

cold side is plumbed to hard water.

• To conserve salt, the installer may have isolated

some fixtures (outside faucets, toilets, etc.) from soft

water. From the outlet of the water softening system,

trace the water flow path, in house plumbing. If soft

water is not directed to a faucet or fixture where

wanted, consult a plumber.

No salt in the brine tank or salt

bridged

• Check for a salt bridge or, if the tank is empty, refill

with recommended salt. Press (for 3 seconds) the

RECHARGE button to start an immediate recharge

and restore soft water supply.

External power supply unplugged

at wall outlet or power cable to

softener not connected. Fuse

blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that

can continuously be switched off

• Check for a loss of electrical power to the water

softening system, due to any of these conditions

and correct as needed. With the power supply

restored, observe the faceplate time display and

read Programming the Control section. NOTE: the

electrical outlet for the softener should be live so it

cannot be accidentally switched off.

Manual bypass valve in bypass

position

• Be sure the bypass valve stem is positioned

properly, with the handle in the OUT position.

Valve drain hose pinched,

plugged, elevated too high or

otherwise restricted

• Any restriction in the drain hose may prevent proper

operation of the nozzle and venturi and reduce or

prevent brine draw during recharge..

Nozzle and venturi dirty,

incorrectly assembled or

damaged

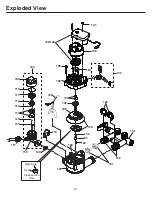

• Refer to Cleaning the Nozzle and Venturi Assembly

instructions. With water pressure to the water

softening system off, take the nozzle assembly

apart. Inspect, clean and replace as needed. Any

foreign particle(s), scratches, nicks, etc. in the

passages can prevent operation. Be sure holes in

the gasket are centred over holes in the housing.

Before you call for service