16

Installation Instructions

C

H

HOT

HOT

HOT

HOT

COLD

COLD

COLD

COLD

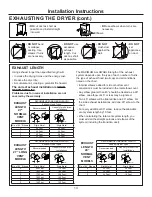

CONNECTING THE WASHER

If not installed, install rubber washer in one end of hot

water hose. Thread hot water hose onto connection

labeled

H

at top rear of washer. Hand tighten, plus an

additional 1/8 turn with pliers.

If not installed, install rubber washer in one end

of cold water hose. Thread cold water hose onto

connection labeled

C

at top rear of washer. Hand

tighten, plus an additional 1/8 turn with pliers.

Move appliance as close to final location as possible,

leaving room for you to make water, drain, electrical

and vent connections to your home.

NOTE:

If longer drain

hose is required, order

drain hose extension kit,

part number WH49X301.

Connect additional drain

hose (contained in kit) to

original hose with hose

clamp (contained in kit).

Insert free end of drain

hose into drain opening

of your home up to drain

hose stopper (do not

remove hose stopper it

prevents siphoning). If

water valves and drain

are built into wall, fasten

drain hose to one of

water hoses with cable

tie provided (ribbed side

on inside). If your drain is

a standpipe, fasten drain

hose to standpipe with

cable tie provided.

WATER SUPPLY REQUIREMENTS

• HOT AND COLD WATER FAUCETS – Must

be within 42” of the appliance water inlet hose

connections. The faucets must be 3/4” garden

hose-type so inlet hoses can be connected.

• WATER PRESSURE – Must be between 20 and

120 pounds per square inch with a maximum

unbalance pressure, hot vs. cold flowing, of 10

pounds per square inch.

• WATER TEMPERATURE – Water heater should be

set to deliver 120°F (50°C) to 150°F (66°C) in the

washer when HOT wash is selected.

• SHUT-OFF VALVES – Both hot and cold water

shut-off valves (faucets) should be supplied.

• LOCATION – Do not install appliance in an area

where the temperature will fall below freezing.

If appliance is stored or transported in freezing

temperatures, be sure all water from the fill and

drain systems has been removed.

DRAIN REQUIREMENTS

• DRAIN RATE – The drain or standpipe must be

capable of accepting a discharge at the rate of 16

gallons per minute.

• DRAIN HEIGHT – The drain height must be 30”

minimum and 96” maximum.

• STANDPIPE DIAMETER – The standpipe diameter

must be 1-1/2” minimum. There MUST be an air

gap around the drain hose in the standpipe. A snug

fit can cause a siphoning action.

• SIPHON BREAK – For a drain facility less than 30”

high, the hose, coupling and clamps provided in the

machine must be used and, in addition, a siphon break

MUST be installed on the back of the machine. Obtain

and use a siphon break kit and follow the instructions

in the kit.

PLUMBING INFORMATION

CONNECTING TO PLUMBING

FACILITIES