Page 9

A d j u s t M i n i m u m Z - A x i s H e i g h t

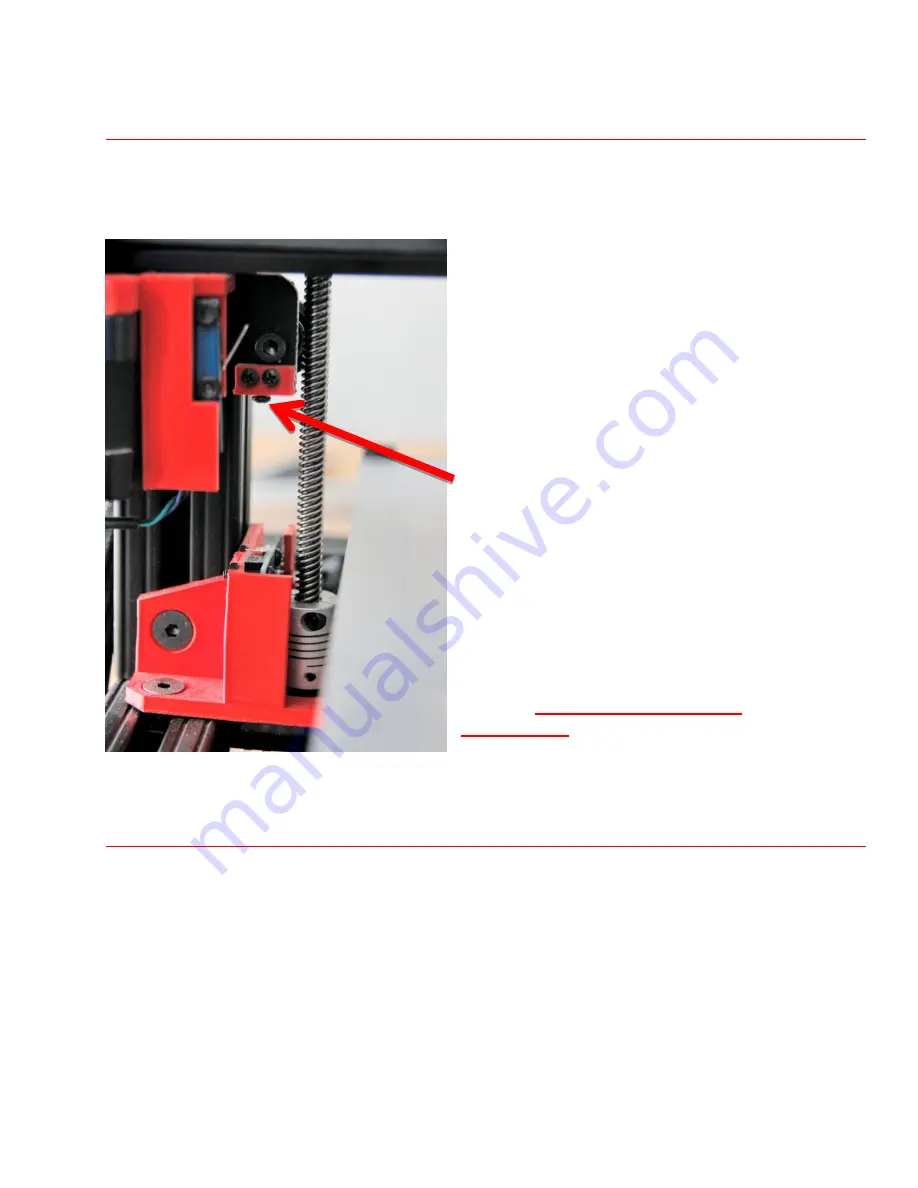

You should also adjust the z-axis endstop screw to set the new zero point if you ever have to adjust the

1

st

layer height. The zero point is the lowest point the extruder will go and this will be the height in

which the print will start. This should be done after adjusting your first print.

Setting the z-axis screw should be done any time you

have to manually adjust the 1

st

layer height. Raising or

lowering this screw will set the z-axis height for your

next print.

Note: To access the set screw you must

raise the extruder by 5”-6”. This can be

done by using the LCD screen and

going to “

Prepare > Move Axis > Move

1mm > Move Z

”. Then simply turn the

knob.

T i p s D u r i n g Y o u r P r i n t

You have some time now so why not read these tips.

1.

Always keep an eye on your print and check on it often especially if it’s the first time running

the file. If any part of the print fails this may destroy the rest of the print and possibly damage

the printer.

2.

You can adjust the speed of your print in real time by simply turning the knob on the LCD

screen. This is very useful if you need to slow down the printer at a difficult area or you notice

the print isn’t cooling enough.