6 Installation and commissioning

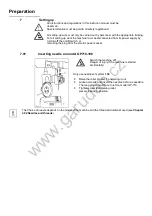

The machine must only be installed and commissioned by qualified personnel!

All relevant safety regulations must be strictly adhered to!

If the machine is delivered without a table, be sure to use a stand and table top that can hold the

weight of the machine with its motor.

It is very important to ensure that the stand of the machine is firm and steady, also during

sewing.

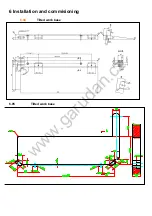

6.01 Installation

The site where the machine is installed must be provided with suitable connections for electric

current.

It must be ensured that the standing surface of the machine site is firm and horizontal, and that

sufficient lighting is provided for.

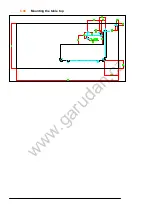

For packing and transportation reasons the table top is in the lowered position. The

table height is adjusted as described below.

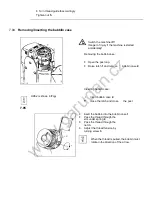

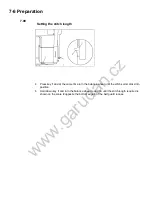

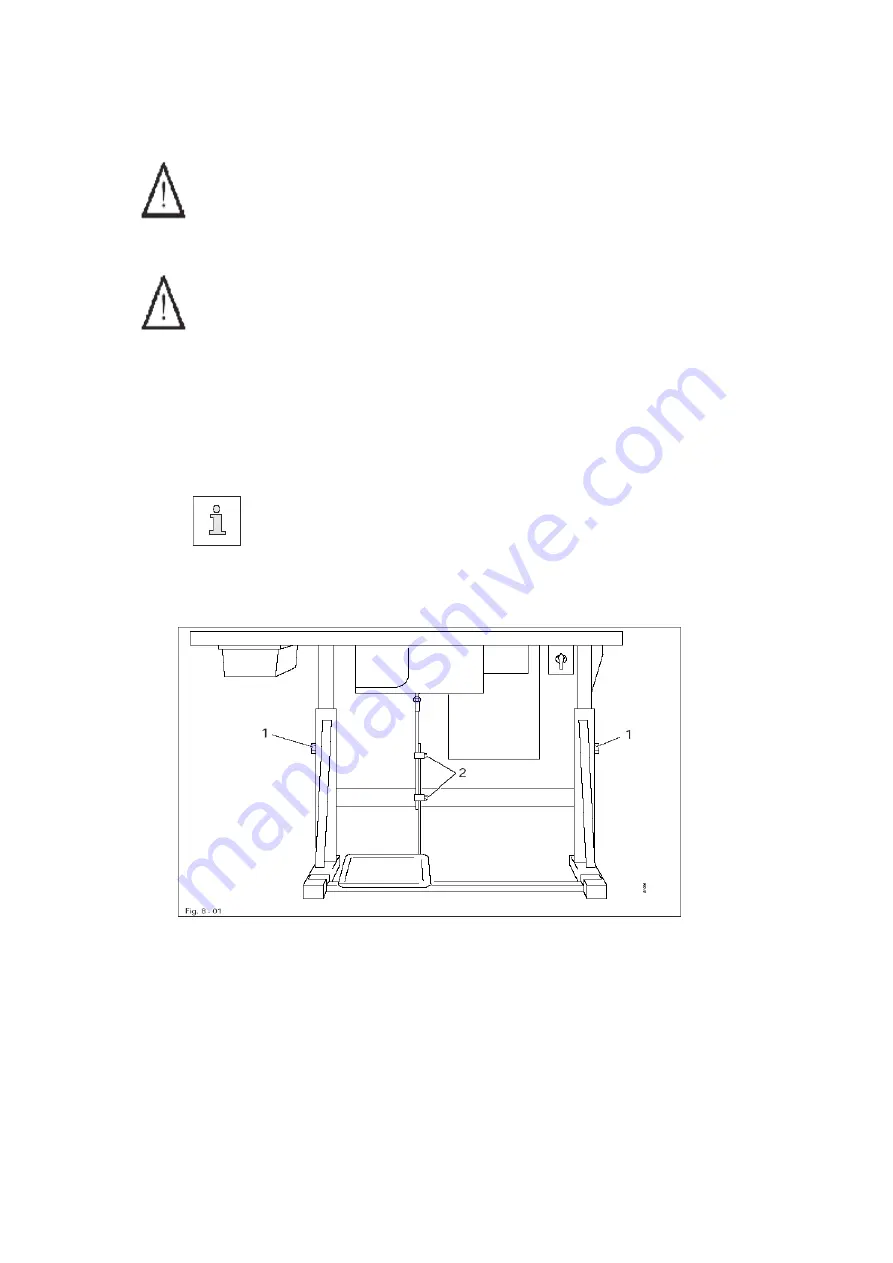

6.01.01 Adusting the table height

●

Loosen screws

1

and

2

and set the table height as required.

●

Firmly tighten screw

1

.

●

Set the required pedal position and tighten screw

2

www.garudan.cz