© ANITA

MP03100EN_180912

17

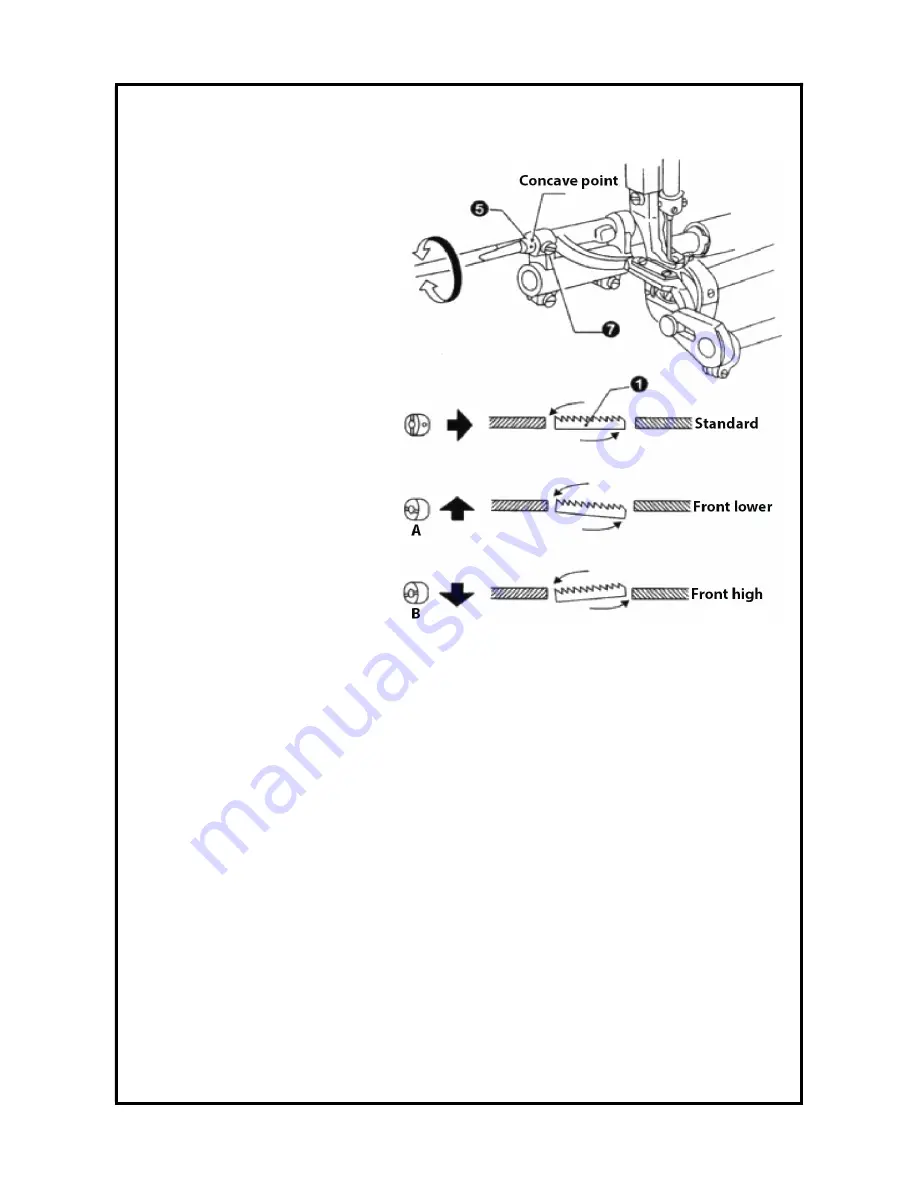

25. ADJUST THE HIGH OF THE FEED DOG

Feed dog standard angle is: when the

feed dog higher than needle plate and

in the highest position. Braces

concave point (5) on the crank

eccentric shaft tags in a horizontal

position.

See Fig. (22).

Turn the wheel make the feed dog

to needle plate and in the

highest position Loosen.

Loosen the braces crank shaft

screw (7).

According to the standard of the

feed dog angle position.

Make the concave point mark 90°

rotation adjustment.

*

Feed dog in front of the lower. can

prevent the fabric wrinkling (picture

A).

* Feed dog in front of the drive up, can prevent the cloth running deviation (picture B).

Tighten braces crank shaft screw (7).

After the feed dog angle adjustment, to adjust the Hight of the dog is necessary.

Figure 22

www.garudan.cz

Содержание GF-3131-447 MH

Страница 31: ...MP03100EN_180625 A ARM MECHANISM 1 2 ANITA 2 ANITA 4 w w w g a r u d a n c z...

Страница 33: ...MP03100EN_180625 A ARM MECHANISM 2 2 ANITA 2 ANITA 6 w w w g a r u d a n c z...

Страница 37: ...MP03100EN_180625 B NEEDLE BAR AND THREAD TAKE ANITA EAD TAKE UP MECHANISM 2 2 ANITA 10 w w w g a r u d a n c z...

Страница 39: ...MP03100EN_180625 C FEED MECHANISM COMPONENTS ANITA OMPONENTS 1 2 ANITA 12 w w w g a r u d a n c z...

Страница 41: ...MP03100EN_180625 C FEED MECHANISM COMPONENTS ANITA OMPONENTS 2 2 ANITA 14 w w w g a r u d a n c z...

Страница 43: ...MP03100EN_180625 D FEED MECHANISM 1 2 ANITA 1 2 ANITA 16 w w w g a r u d a n c z...

Страница 45: ...MP03100EN_180625 D FEED MECHANISM 2 2 ANITA 2 2 ANITA 18 w w w g a r u d a n c z...

Страница 47: ...MP03100EN_180625 E PRESSER FOOT MECHANISM ANITA ECHANISM ANITA 20 w w w g a r u d a n c z...

Страница 49: ...MP03100EN_180625 F ROTARY HOOK MECHANISM ANITA ECHANISM ANITA 22 w w w g a r u d a n c z...

Страница 51: ...MP03100EN_180625 G THREAD TRIMMER MECHANISM ANITA ECHANISM 1 2 ANITA 24 w w w g a r u d a n c z...

Страница 53: ...MP03100EN_180625 G THREAD TRIMMER MECHANISM ANITA ECHANISM 2 2 ANITA 26 w w w g a r u d a n c z...

Страница 55: ...MP03100EN_180625 H LUBRICATION ANITA ANITA 28 w w w g a r u d a n c z...

Страница 57: ...MP03100EN_180625 I REVERSE FEED COMPONENTS ANITA OMPONENTS ANITA 30 w w w g a r u d a n c z...

Страница 59: ...MP03100EN_180625 J INBUILT FOOT LIFT STRUCTURE ANITA RUCTURE ANITA 32 w w w g a r u d a n c z...

Страница 61: ...MP03100EN_180625 K IMPACT CONTROLLER SYST ANITA PACT CONTROLLER SYSTEM ANITA 34 w w w g a r u d a n c z...

Страница 63: ...MP03100EN_180625 L ACCESSORIES ANITA ANITA 36 w w w g a r u d a n c z...