ANITA ©

MP00100EN_170907

21

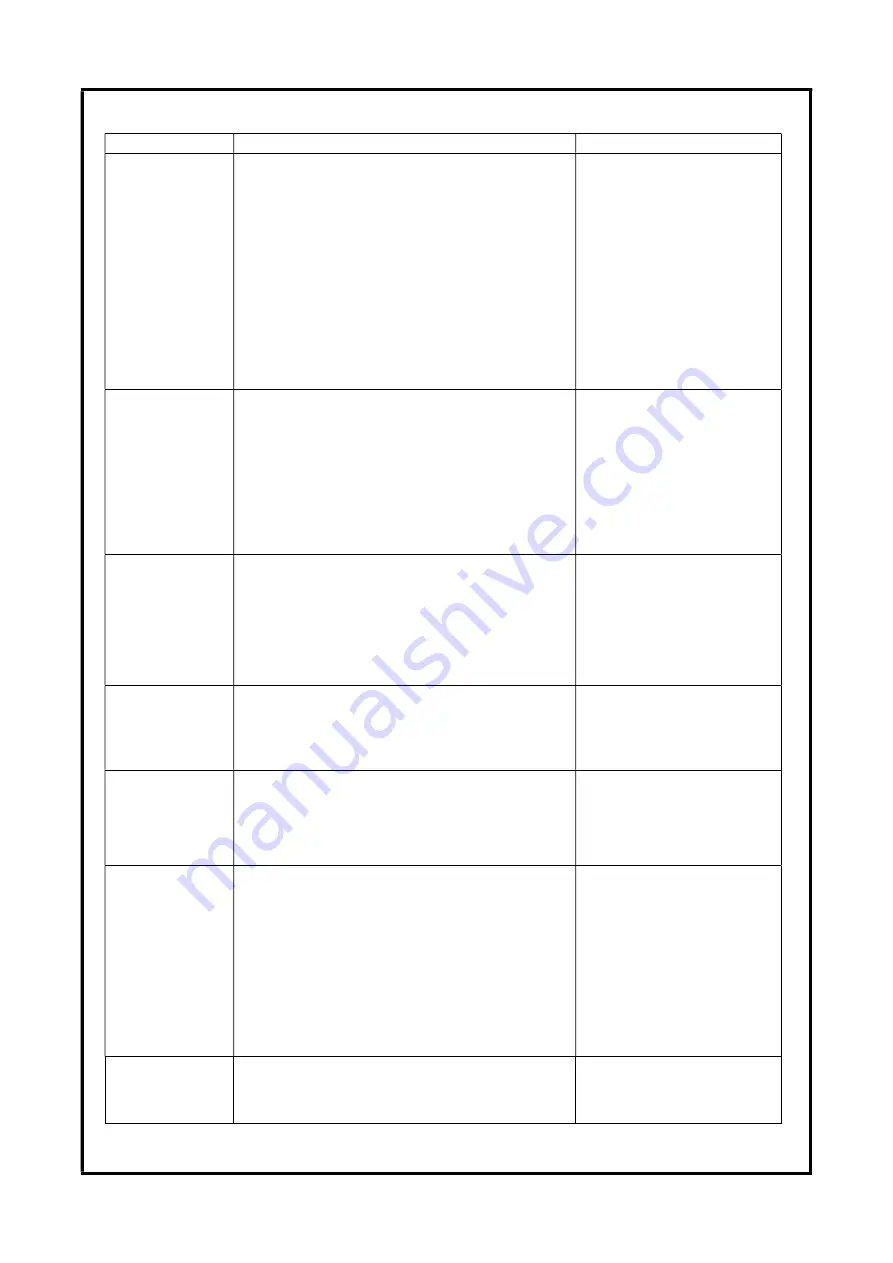

28. TROUBLE AND CORRECTIVE MEASURES

Trouble

Cause

Coorective measures

Thread breakage

(thread frays or

wears out)

1. The thread path, needle point, hook point or bobbin case

positioning finger has scratches

2. The needle thread tension is too high

3. The needle hits the hook points

4. The needle thread tension od too low

5. The thread take-up spring has an exceessively high

tension while it has an excessively small stroke

6. The timing between the needle and hook is too early or

late.

1 Remove the scratches on the

hook point using a fine sand paper.

2. Properly adjust the needle

thread tension

3. See "13. Neelde-to-hook

relationship"

4. Properly adjust the needle

thread tension

5. Decrease the tension and

increase the stroke

6. See "13. Neelde-to-hook

relationship"

Stitch skipping

1. The clearance between the needle and the hook point is

too large

2. The timing between the needle and hook is too aerly or

late

3. the presser foot pressure is too low

4. The clearance between the top edge of the needle eylet

and the hook point is not correct

5. The size of the needle is wrong

1.See "13. Neelde-to-hook

relationship"

2. See "13. Neelde-to-hook

relationship"

3. Increase the presser foot

pressure

4. See "13. Neelde-to-hook

relationship"

5. Replace the needle by one which

one grade thicker

Loose stitches

1. The thread has not been the passed the through notch of

the bobbin case tension spring

2. The thread path is poorly finished

3 The bobbin does not rotate smoothly

4.The bobbin thread tension is too low

5. The bobbin thread has been wound too tight

1. Properly thread the bobbin case

2. Grind it using a fine sand paper

of a buff

3. Replace the bobbin or hook

4. Properly adjust the tension

5. Decrease the bobbin thread

winding tension

The thread slips off

the needle up on

being trimmed

1.The tension of the auxiliary thread tension controller is

too high - on controller is too high

2. The thread trimming timing is too early

3. The retuirning force of the thread take-up spring is too

high

1. Descrease the tension

2. See "21. Adjust the thread

trimming cam"

3. See "9. Thread take-up spring

The needle thread

cannot be trimmed

while the bobbin

thread can be

trimmed

1. The last stitch has been skipped (the clearance between

the needle and the hook is too large)

1.See "13. Neelde-to-hook

relationship"

Both needle and

bobbin threads

cannot be trimmed

1. The thread trimming timing os wrong

2. The knife has been damaged

3. The knife pressure is inadequate

4. The home position of the movable knife is inaccurate

5. The movable knife fails to work

6. The thread trimming solenoid fails to work

1. See "21. Adjust the thread

trimming cam"

2. Replace the knife

3. Increase the knife pressure

4. See "21. Adjust the thread

trimming cam"

5. Check it by actuating it by hand

6. Check the motor solenoid for

proper operation

Thread cannot be

trimmed sharply

1. The thread trimming timing is wrong

2. The knife pressure is inadequate

3. The knife bledeisblunt

1. See "21. Adjust the thread

trimming cam"

2. Increase the knife pressure

3. Replace the knife

www.garudan.cz

Содержание anita GC-3317 Series

Страница 22: ...ANITA MP00100EN_170907 22 w w w g a r u d a n c z...

Страница 26: ...ANITA MP00100EN_170907 4 A FRAME MISCELLANEOUS COVER COMPONENTS 1 3 w w w g a r u d a n c z...

Страница 28: ...ANITA MP00100EN_170907 6 A FRAME MISCELLANEOUS COVER COMPONENTS 2 3 w w w g a r u d a n c z...

Страница 30: ...ANITA MP00100EN_170907 8 A FRAME MISCELLANEOUS COVER COMPONENTS 3 3 w w w g a r u d a n c z...

Страница 32: ...ANITA MP00100EN_170907 10 B MAIN SHAFT UPRIGHT SHAFT COMPONENTS w w w g a r u d a n c z...

Страница 34: ...ANITA MP00100EN_170907 12 C NEEDLE BAR THREAD TAKE UP LEVER COMPONENTS w w w g a r u d a n c z...

Страница 36: ...ANITA MP00100EN_170907 14 D NEEDLE BAR ROCKING MOTION MECHANISM COMPONENTS w w w g a r u d a n c z...

Страница 38: ...ANITA MP00100EN_170907 16 E UPPER FEED MECHANISM COMPONENTS w w w g a r u d a n c z...

Страница 40: ...ANITA MP00100EN_170907 18 F PRESSURE BAR KNEE LIFTER COMPONENTS 1 3 w w w g a r u d a n c z...

Страница 42: ...ANITA MP00100EN_170907 20 F PRESSURE BAR KNEE LIFTER COMPONENTS 2 3 w w w g a r u d a n c z...

Страница 44: ...ANITA MP00100EN_170907 22 F PRESSURE BAR KNEE LIFTER COMPONENTS 3 3 w w w g a r u d a n c z...

Страница 46: ...ANITA MP00100EN_170907 24 G LOWER FEED MECHANISM COMPONENTS 1 2 w w w g a r u d a n c z...

Страница 48: ...ANITA MP00100EN_170907 26 G LOWER FEED MECHANISM COMPONENTS 2 2 w w w g a r u d a n c z...

Страница 50: ...ANITA MP00100EN_170907 28 H FEED ADJUSTMENT MECHANISM COMPONENTS 1 2 w w w g a r u d a n c z...

Страница 52: ...ANITA MP00100EN_170907 30 H FEED ADJUSTMENT MECHANISM COMPONENTS 2 2 w w w g a r u d a n c z...

Страница 54: ...ANITA MP00100EN_170907 32 I HOOK DRIVE SHAFT COMPONENTS w w w g a r u d a n c z...

Страница 56: ...ANITA MP00100EN_170907 34 J UPPER THREAD TENSION REGULATOR MECHANISM COMPONENTS w w w g a r u d a n c z...

Страница 58: ...ANITA MP00100EN_170907 36 K ACCESSORIES w w w g a r u d a n c z...

Страница 61: ...ANITA MP00100EN_170907 39 w w w g a r u d a n c z...