SB--7--622 Page 10

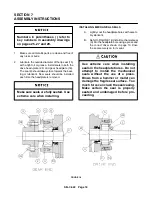

SAFETY PRECAUTIONS

1.

Do not operate blower with open inlet or outlet

port.

2.

Do not exceed specified vacuum or pressure

limitations.

3.

Do not operate above or below recommended

blower speed range.

4.

Blower is not to be used where non--sparking

equipment is specified.

5.

Do not operate without belt guard or coupling

shield.

Do not exceed sheave or coupling

manufacturers’ rim speed limit.

6.

The blower and blower discharge piping may be

extremely hot and can cause skin burns on contact.

7.

Prolonged exposure may require ear protection.

TROUBLE SHOOTING

No matter how well the equipment is designed and

manufactured, there may be times when servicing will

be required due to normal wear, the need for adjust-

ment, or various external causes. Whenever equip-

ment needs attention, the operator or repairman should

be able to locate the cause and correct the trouble

quickly. The Trouble Shooting Chart below is provided

to assist the mechanic in those respects.

PROBLEM

POSSIBLE CAUSES

SOLUTION

1.

Unit out of time.

1.

Retime impellers.

2.

Distortion due to improper

2.

Check mounting alignment and

mounting or pipe strains.

relieve pipe strains.

Knocking

3.

Excessive pressure differential.

3.

Reduce to manufacturer’s

recommended pressure. Examine

relief valve, re-set if necessary.

4.

Worn gears.

4.

Replace timing gears.

5.

Worn bearings.

5.

Replace bearings.

1.

Too much oil in gear case.

1.

Reduce oil level.

Excessive blower

2.

Too low operating speed.

2.

Increase blower speed.

temperature.

3.

Clogged filter or muffler.

3.

Remove cause of obstruction.

4.

Excessive pressure differential.

4.

Reduce pressure differential

across the blower.

5.

Worn impeller clearances.

5.

Replace impeller.

6.

Internal contact.

6.

Correct clearances.

1.

Insufficient assembled

1.

Correct clearances.

clearances.

Impeller end

2.

Case or frame distortion.

2.

Check mounting and pipe strain.

or tip drag.

3.

Excessive operating pressure.

3.

Remove cause.

4.

Excessive operating temperature.

4.

Remove cause.

Lack of volume.

1.

Slipping belts.

1

Tighten belts.

2.

Worn clearances.

2.

Re-establish proper clearances.

Excessive bearing

1.

Improper lubrication.

1.

Correct lubrication level. Replace

or gear wear.

dirty oil.

1.

Headplate, gear case or

1.

Clean vents.

Loss of oil.

drive cover vents plugged.

2.

Worn seal.

2.

Replace seals.

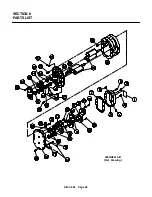

Содержание LEGEND GAF P Series

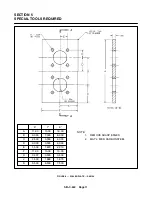

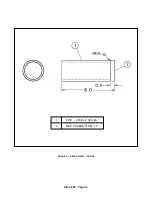

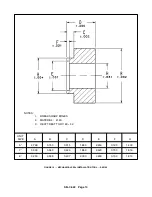

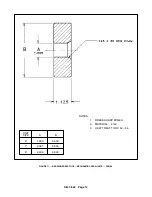

Страница 19: ...SB 7 622 Page 12 1 PIPE STEEL 2 SCH 80 2 MED CARBON STEEL 1 2 FIGURE 9 GEAR DRIVER SK2150...

Страница 32: ...SB 7 622 Page 25 SECTION 8 PARTS LIST 300GAF810 B Ref Drawing...

Страница 34: ...SB 7 622 Page 27 300GAG810 A Ref Drawing...

Страница 36: ...SB 7 622 Page 29 300GAH810 A Ref Drawing...

Страница 39: ......