22

|

www.gd-elmorietschle.com

© Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

Maintenance and repair

H

M

L

I

K

7.2.3 Lubrication

NOTICE

Always change the oil when the machine is at

operating temperature and in an atmospherically

ventilated area. If it is not completely emptied the

amount that can be refilled is reduced.

he waste oil must be disposed of in compliance with

the local environmental protection regulations.

If you change the type of oil, empty the oil tank

completely.

The oil level must be checked at least once a day,

if necessary top the oil up to the upper edge of the

sight glass (Fig. 7/I) First oil change after 500 hours

of operation. Subsequent oil changes after 500-

2000 hours of operation. Reduce the change inter-

vals accordingly depending on how contaminated

the discharged medium is.

Only vacuum pump oils as per DIN 51506-VDL, ISO

6743-3 DVA and DVC or a synthetic oil released by

Elmo Rietschle may be used. The viscosity of the

oil must comply with ISO VG 100 as per DIN 51519.

Elmo Rietschle oil types:

MULTI-LUBE 100 (mineral

oil) and SUPER-LUBE 100 (synthetic oil) see also oil

recommendation plate (Fig. 7/M)).

If the oil is subject to high temperatures (ambient or

intake temperatures over 30 °C, insufficient cooling,

60 Hz operation etc.) the oil change interval may be

extended by using the recommended synthetic oil.

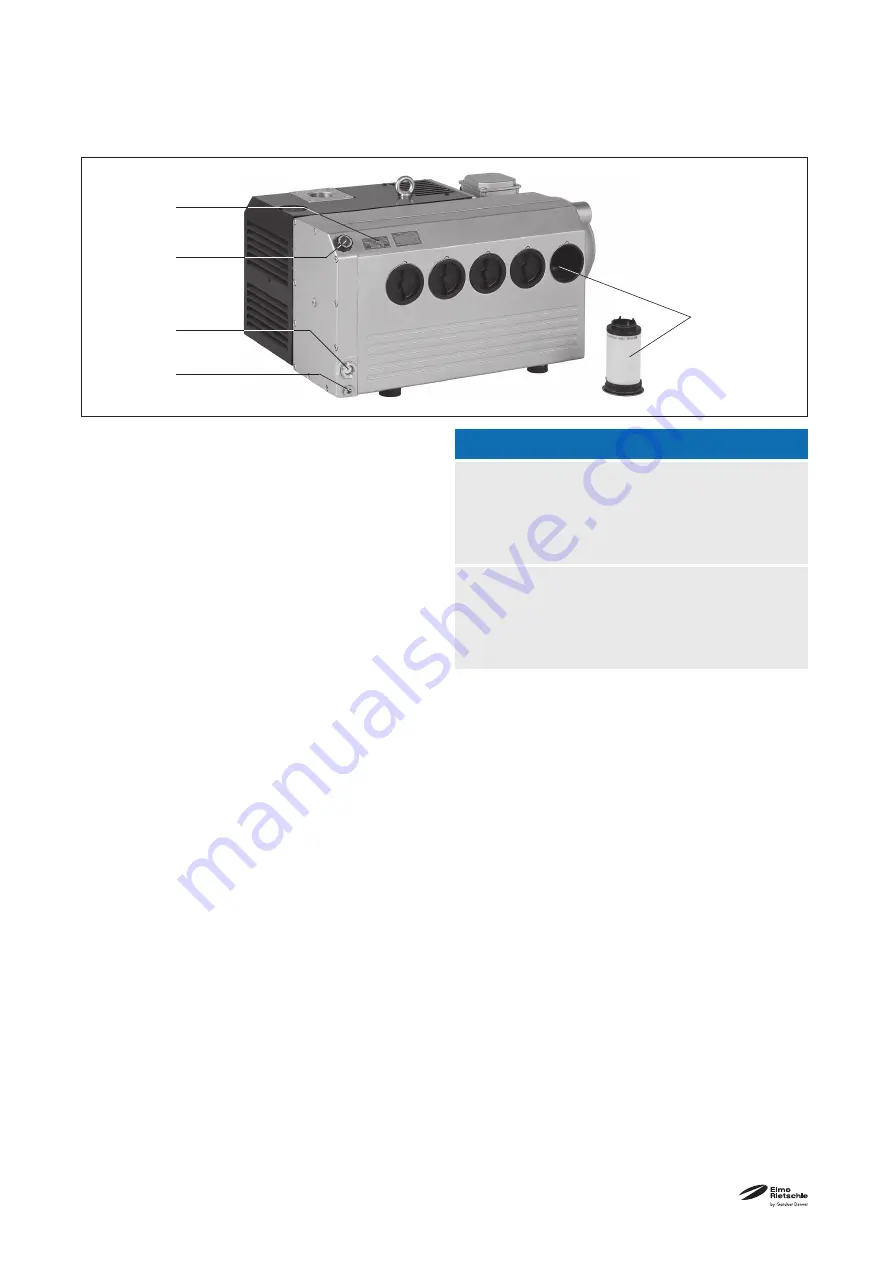

Fig. 7 Lubrication and removing oil

H

Oil filling point

I

Oil sight glass

K

Oil discharge point

L

Oil separator element

M

Oil recommendation plate