17

RG66002124 - Rev 05

All copying, even partial, of this manual is strictly forbidden

MCA

12

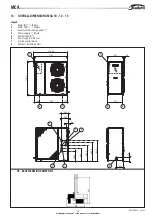

WATER CIRCUIT

When setting up the water circuit of the unit, it is advisable to follow the

directions below and in any case comply with local or national regulations.

Connect the pipes to the chiller using flexible couplings to prevent the

transmission of vibrations and to compensate thermal expansions.

It is recommended to install the following components on the pipes:

- Temperature and pressure indicators for routine maintenance and monitoring

of the unit. Checking the pressure on the water side will enable you to verify

whether the expansion tank is working efficiently and to promptly detect

any water leaks within the equipment.

- Traps on incoming and outgoing pipes for temperature measurements,

which can provide a direct reading of the operating temperatures.

- Regulating valves (gate valves) for isolating the unit from the water circuit.

- Metal mesh filter (incoming pipes), with a mesh not to exceed 1 mm, to

protect the exchanger from scale or impurities present in the pipes.

- Air vent valves, to be placed at the highest points of the water circuit for

the purpose of bleeding air. (The internal pipes of the unit are fitted with

small air vent valves for bleeding the unit itself: this operation may only be

carried out when the unit is disconnected from the power supply).

- Drainage valve and, where necessary, a drainage tank for emptying out the

equipment for maintenance purposes or when the unit is taken out of

service at the end of the season. (A 1" drainage valve is provided on the

optional inertial storage reservoir: this operation may only be carried out

when the unit is disconnected from the power supply).

Legend

GA

Vibration-damping coupling (not supplied)

D

P

Differential pressure switch

EV

Evaporator (R407C/water exchanger)

MA

Water pressure gauge

P

Water pump

RR

Circuit filling tap

RS

Circuit emptying tap

VAS

Automatic air vent valve

SIA

Inertial water storage reservoir

VE

Expansion tank

VS

Safety valve

MCA - CB

from the system

to the system

RR

VS

EV

D

P

MA

VAS

IN

OUT

RS

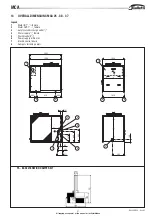

RR

VS

EV

D

P

P

RS

MA

VAS

IN

OUT

SIA

VE

It is of fundamental importance that the incoming water supply is hooked up

to the connection marked "Water Inlet"

Otherwise the evaporator would be exposed to the risk of freezing since the

antifreeze thermostat would not be able to perform its function; moreover the

reverse cycle would not be respected in the cooling mode, resulting in

additional risks of malfunctioning.

The dimensions and position of plumbing connections are shown in the

dimension tables at the back of the manual.

The water circuit must be set up in such a way as to guarantee that the

nominal flow rate of the water supplied to the evaporator remains constant

(+/- 15%) in all operating conditions.

A standard feature of MCA units is a device for controlling the flow rate (flow

switch or differential pressure switch) in the water circuit in the immediate

vicinity of the evaporator.

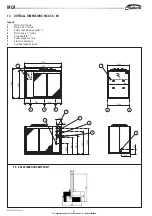

RR

VS

EV

D

P

P

MA

VAS

IN

OUT

RS

VE

MCA - CP

MCA - CS

from the system

to the system

from the system

to the system