36

08..09 Not used

Errors 08 and 09 are reserved.

Fatal Errors (excluding fatal startup errors)

Errors 10 through to 29 all cause the processor to stop. The errors are displayed but beeps are not

sounded. The pump must be reset after one of these errors.

10..15 Pump Control State Errors (Pump A..F)

This indicates an attempt to enter an undefined side control state on a particular pump number.

16

Stack Error

The stack is continuously checked. If a stack overflow occurs, error 16 will be displayed.

This check is performed in the dynchk module.

17

Display Error

If a Display error is indicated, a translation error occurred when writing to one of the 7 segment LCD

displays.

18

Variable Range Error

Error 18 indicates a global software parameter (ie pump, grade or price etc) is not within its normal

range. This can be a result of corruption of the internal data RAM, which may cause unpredictable

results.

This check is not limited to any particular module, but is used by any procedure that requires range

checking.

19

Dollar Maths Error

At the end of a delivery, the delivery dollar calculations are performed (ie price per litre multiplied by

litres equals dollars). Error 19 indicates an error occurred in the calculations. A likely cause for this

would be a price change (or corruption of the price variable) during a delivery.

20

Litres Maths Error

At the end of a delivery, the delivery quantity accumulation calculation is made (ie, total number of

encoder counts for the delivery time multiplied by the encoder constant equals the litres displayed).

Error 20 indicates an error occurred in the accumulation.

If this is not the case, it is probable that the encoder is going too fast, such that the incoming encoder

counts (which are accumulated under interrupt control) are not being "consumed" quickly enough by

the maths routines to prevent a rollover.

21

Clock Error

A Clock Error indicates that the current time variable (which is used to time tag events) is not

incrementing.

22

Motor Control Error

Error 22 indicates that an attempt was made to turn a motor on or off when it was already in that state

(according to the software).

23

Solenoid Control Error

This indicates that an attempt was made to open or close a solenoid valve when it was already in that

state (according to the software). It will also occur (except in diagnostic mode) if an attempt is made to

turn on a solenoid valve when the corresponding motor is not on.

24

Power Fail

This error indicates the system entered its main initialisation procedure (which should only happen on

power up or as a result of certain diagnostic functions), but the power fail flag does not show power

failed.

This may occur in the event of a total power loss (including the lithium battery) such that the XRAM

was corrupted, or if the power fail procedures are not functioning correctly.

25

Input Processor to main failure

This error will occur if the system expects an Input Processor to be present (i.e., it was auto-detected at

power up) but is no longer receiving any comms response from it.

This would be caused by either a fatal error in the input processor, or a physical loss of connection on

the serial link between the two processor boards.

26

Main to Input Processor failure

This error will occur if the system expects an Input Processor to be present (i.e., it was auto-detected at

power up) and is receiving comms response from it, but the Input Processor is not receiving data from

the main processor.

Содержание Apollo 3000

Страница 1: ...Apollo 3000 Set up Installation Parts Manual...

Страница 2: ......

Страница 4: ......

Страница 15: ...11 Float Switch 89778 Float Swt Mtg Angle only 89749 Float Switch Bracket Assembly...

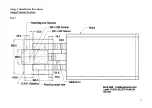

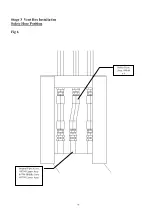

Страница 26: ...22 Stage 1 Installation Procedure Sump Column Position Fig 2...

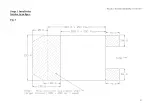

Страница 27: ...23 file gme c docum pec apollo2 fig 2 manual doc Stage 1 Installation Service Area Spec Fig 3...

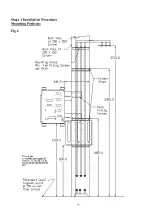

Страница 28: ...24 Stage 1 Installation Procedure Mounting Positions Fig 4...

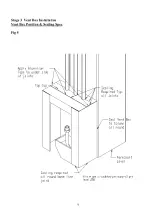

Страница 29: ...25 Stage 3 Vent Box Installation Vent Box Position Sealing Spec Fig 5...

Страница 46: ...Apollo 2000 Set up Installation Parts Manual...