GAR CUT (V. INDUSTRIAL). Instructions Manual

19

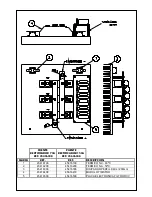

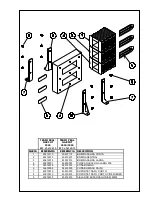

3.3 START-UP PROCESS. GAR CUT 2500/4000/5000.

The machine must be used by as few people as possible. The equipment must never be used by untrained

operators.

The sequence to carry out the equipment start-up is described below:

⇒

Connect the torch to CN3. Check it is connected properly.

⇒

Secure the safety cap of the torch. (The coupling of the security system can be seen in the appendices).

⇒

Connect the earth cable to W and place it in the cutting piece. The electrical connection must be perfect.

⇒

Place the ON/OFF switch in “ON” position. Light L1 comes on.

⇒

Check that the red (L2) and amber (L3) lights are not on.

⇒

Determine suitable cutting power through P1.

⇒

Lightly press the torch pushbutton. Air will start to flow.

⇒

Check that the pressure gauge M mark 5.5-6 bar. There must be airflow.

⇒

Press the torch pushbutton. Formation of arc. Light L4 comes on.

⇒

The pilot arc which has formed is timed at 2 sec. In the event that the cutting operation is not started the

arc will automatically go out.

⇒

Begin to cut. Light L5 comes on.

3.4 CUTTING PROCESS. GENERAL RECOMMENDATIONS.

Before proceeding to carry out the cut, the correct cutting intensity must be determined depending on the

work to be carried out.

When inserting a new electrode in the cutting torch proceed to brush it to eliminate possible surface

insulating layers.

When using nozzle and long electrodes, for security reasons, shield cup Ref. 51957/G should be

incorporated.

Form the pilot arc outside the part. Before forming the arc we recommend pressing the pushbutton

slightly in order to have a prior airflow. The pilot arc goes out automatically after two seconds if no

cutting is done.

If, after quite a long cutting process, we see that the cutting torch is heating up, we advise letting the

post-flow of air cool down the torch.

Determine the correct cutting speed. The penetration as well as the cutting flash depend directly on the

speed used in the process. The correct speed is considered to be that which causes a maximum

inclination of the arc projected of 7 to 15º with respect to the perpendicular of the part.

Do not touch the cutting part with the nozzle. Keep a minimum distance of 5 mm. Use an cutting guide

shoe.

"Polish the electrode"

Carry out this operation whenever there are problems in igniting the arc.

Any elements, accessory or instrument which is added to the equipment must maintain the

basic safety conditions of the equipment. All added equipment will comply with the

Standards and Regulations in force.

WARNING !

IF THE FRONT SAFETY PROTECTION OF THE TORCH HAS NOT BEEN INSERTED,

THE MACHINE WILL NOT BE OPERATIVE.