5

Governors America Corp. © 2021 Copyright All Rights Reserved

ESD5500E Series Speed Control Unit 2-2021-F2 PIB1002

ProceDure

Start the engine and maintain at an idle speed for a period of time

prior to accelerating to the operating speed. This method separates

the starting process so that each may be optimized for the lowest

smoke emissions.

1. Replace the connection between Terminals M & G with a tog-

gle switch or a normally open water jacket temperature switch.

Other optical switch combinations can be used.

2. Start the engine.

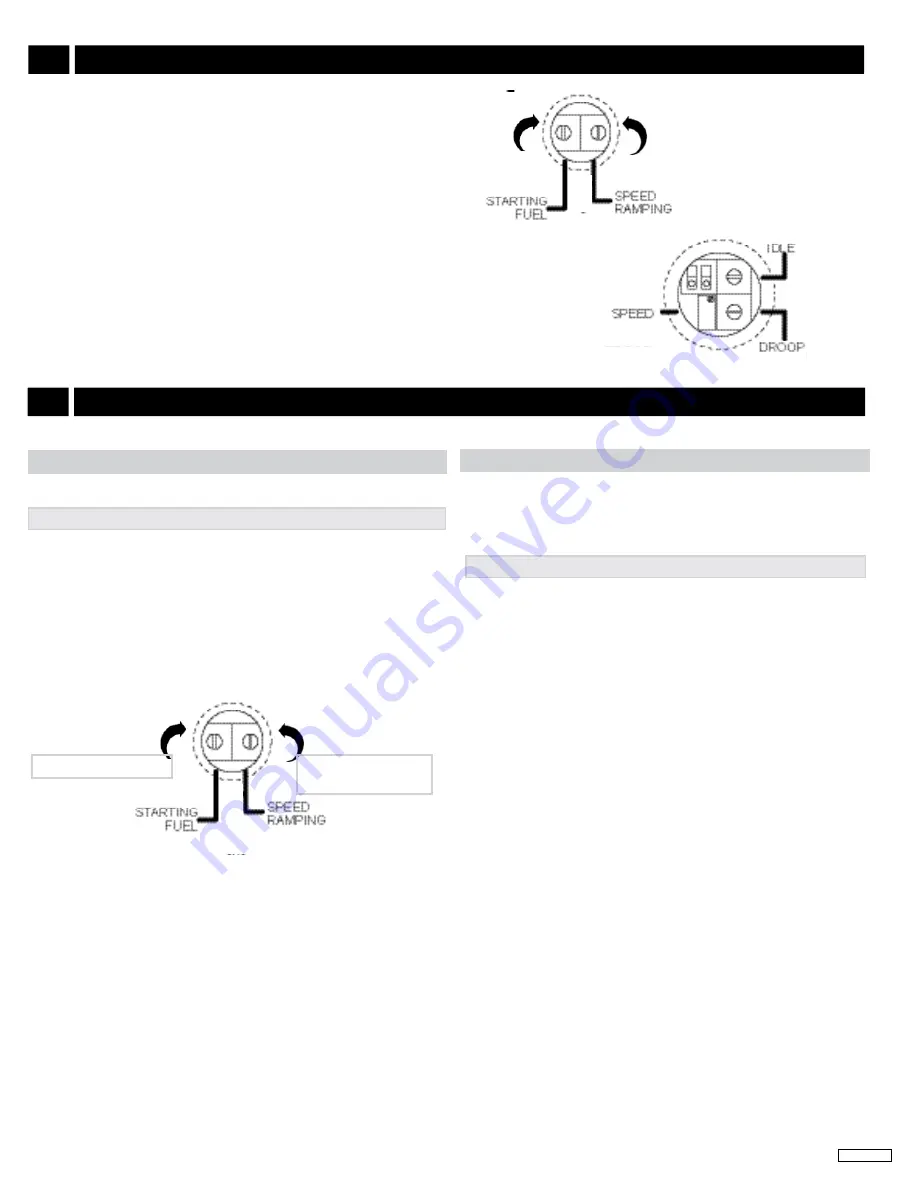

3. If the starting smoke is excessive, the STARTING FUEL may

need to be adjusted slightly CCW.

4. If the starting time is too long, the STARTING FUEL may need

to be adjusted slightly CW.

5. When the switch opens, adjust the SPEED RAMPING for the

least amount of smoke when accelerating from idle speed to

rated speed.

One of two methods of operation for the ESD5500E may be selected: Operating Speed or Idle.

metHoD 1 - oPeratInG SPeeD

ProceDure

Start the engine and accelerate directly to the operating speed (Gen-

erator Sets, etc.).

metHoD 2 - IDLe SPeeD

10

mEThODS OF OPERATION

1. Remove the connection between Terminals M and G.

2. Start the engine and adjust the SPEED RAMPING for the least

smoke on acceleration from idle to rated speed.

3. If the starting time is too long, the STARTING FUEL may need to

be adjusted slightly clockwise (CW).

full ccW = fastest

full cW = maX fuel

9

STARTINg FUEl ADJUSTmENT

The engine’s exhaust smoke at start-up can be minimized by complet-

ing the following adjustments:

1. Place the engine in idle by connecting Terminals M and G.

2. Adjust the IDLE speed for as low a speed setting as the appli-

cation allows. Idle speed must be set for proper start fuel and

speed ramping function, even if the idle feature is not used.

3. Adjust the STARTING FUEL CCW until the engine speed begins

to fall. Increase the STARTING FUEL slightly so that the idle

speed is returned to the desired level.

4. Stop the engine.