00029992.DOC, Version 1.3

47/90

Error Messages

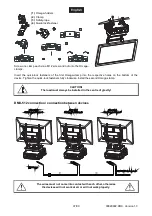

When you turn on the fixture, it will make a reset first. The display may show an error message while

there are problems with one or more channels. The error message stands for the channels equipped

with a testing sensor.

When the display shows “PAN”, it means there is some error in the PAN channel. If there are errors

on several channels at the same time, you may see error messages flash repeatedly for 5 times Then

the fixture will generate a reset signal, all stepper motors will reset. If the error messages maintain

after performing a reset twice, the channels which have errors can not work properly, others can

work as usual.

(PAN movement error) This message will appear after the reset of the device if the magnetic-indexing circuit

malfunction (sensor failed or magnet missing) or the stepping-motor is defective (or its driving IC on the main

PCB). The plate is not located in the default position after the reset.

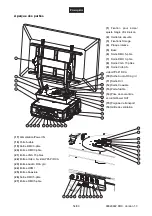

CLEANING AND MAINTENANCE

The operator has to make sure that safety-relating and machine-technical installations are inspected by an

expert after every four years in the course of an acceptance test.

The operator has to make sure that safety-relating and machine-technical installations are inspected by a

skilled person once a year.

The following points have to be considered during the inspection:

1) All screws used for installing the devices or parts of the device have to be tighly connected and must not

be corroded.

2) There must not be any deformations on housings, fixations and installation spots (ceiling, suspension,

trussing).

3) Mechanically moved parts like axles, eyes and others must not show any traces of wearing (e.g. material

abrading or damages) and must not rotate with unbalances.

4) The electric power supply cables must not show any damages, material fatigue (e.g. porous cables) or

sediments. Further instructions depending on the installation spot and usage have to be adhered by a

skilled installer and any safety problems have to be removed.

Disconnect from mains before starting maintenance operation!

DANGER TO LIFE!

We recommend a frequent cleaning of the device. Please use a moist, lint-free cloth. Never use alcohol or

solvents!

The cooling-fans should be cleaned monthly.

Do not operate this device with opened cover!

The interior of the device should be cleaned at least annually using a vacuum-cleaner or an air-jet.

There are no serviceable parts inside the device except for the fuse. Maintenance and service operations are

only to be carried out by authorized dealers.