9

INZ-TN5ZBAS-E

7. insPECtion AnD MAintEnAnCE

7.1 Daily inspection

Check to make sure that extractor is properly warmed up.

7.2 Periodical inspection/maintenance (standard)

Item

Remark

Cleaning of wire gauze filter:

Replacement once every several days to 3

months, or when use is no longer possible

Clean or replace according to the amount of

dust deposits in exhaust gas.

Replacement of O-ring or packing:

(at inspection/replacement of wire gauze

filter), Once/6 months for high temperature,

once a year for general use

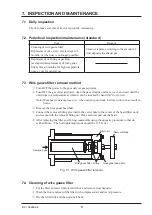

7.3 Wire gauze filter removal method

①

Turn OFF the power to the gas analyzer gas aspirator.

②

Turn OFF the gas extractor power, open the gas extractor unit case cover, and wait until the

unit drops to a temperature at which it can be touched by hand (50°C or lower).

Note) Wear heat-resistant gloves, etc. when carrying out work. Failure to do so may result in

burns.

③

Remove the hexagonal head bolt.

④

Connect the removal fitting provided to the screw hole in the center of the head (filter unit),

and secure with the removal fitting nut. Once secured, pull out the head.

⑤

After replacing the filter and O-ring, reassemble using the opposite procedure to that de

-

scribed above. (The bolt tightening torque should be 12.5 N·m.)

Removal fitting

Hexagonal head bolt

O-ring

Filter unit

Wire gauze filter

Sampling gas

Fig. 7-1 Wire gauze filter removal

7.4 Cleaning of wire gauze filter

①

Put the filter in water while it is still hot, and remove dust deposits.

②

Wash the front and rear of the filter with compressed air and water pressure.

③

Dry the filter fully and then mount it back.