5

INZ-TN5ZBAS-E

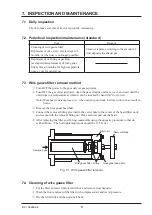

5.3 Sampling tube

(1) The sample line pipe material must not alter the composition of the sample gas, and must be cor

-

rosion resistant.

The recommended material is a Teflon tube. Please prepare pipe joints (for Rc1/2).

(2) Prepare pipe joints (for Rc1/2) if using pipes such as SUS pipe or SGP pipe.

(3) SUS pipe is recommended for the blowback line pipe material.

(4) Connect the pipes to the respective connections as shown in Fig. 5-3.

1

2

3

4

Blow 2 connection

Sample connection

Blow 1 connection

Fig. 5-3

(5) Refer to Fig. 5-4 for an example for a blowback line pipe.

Sample

Blow 1

Blow 2

Motorized valve 3

Motorized valve 2

Filter

regulator

Motorized valve 1

To analyzer

(sample line)

Instrument air

or nitrogen

0.4 to 0.7 MPa

300 L/min

Fig. 5-4

(6) Ensure that the sample pipe from the gas extractor inclines downward by 15° or more to allow

condensed water to flow.

(Sagging is not permitted at any point in the middle of the pipe) Particular attention should be

paid to the inclination at the gas extractor exit (see Fig. 5-5).

Ground

Ground

Pipe

Pipe

15° or more

Extractor

Extractor

Gas analyzer system

Gas analyzer system

Pay attention to sagging in middle

Fig. 5-5