070.610-IOM (JUL 21)

Page 4

RWF II Rotary Screw Compressor Units

General Information

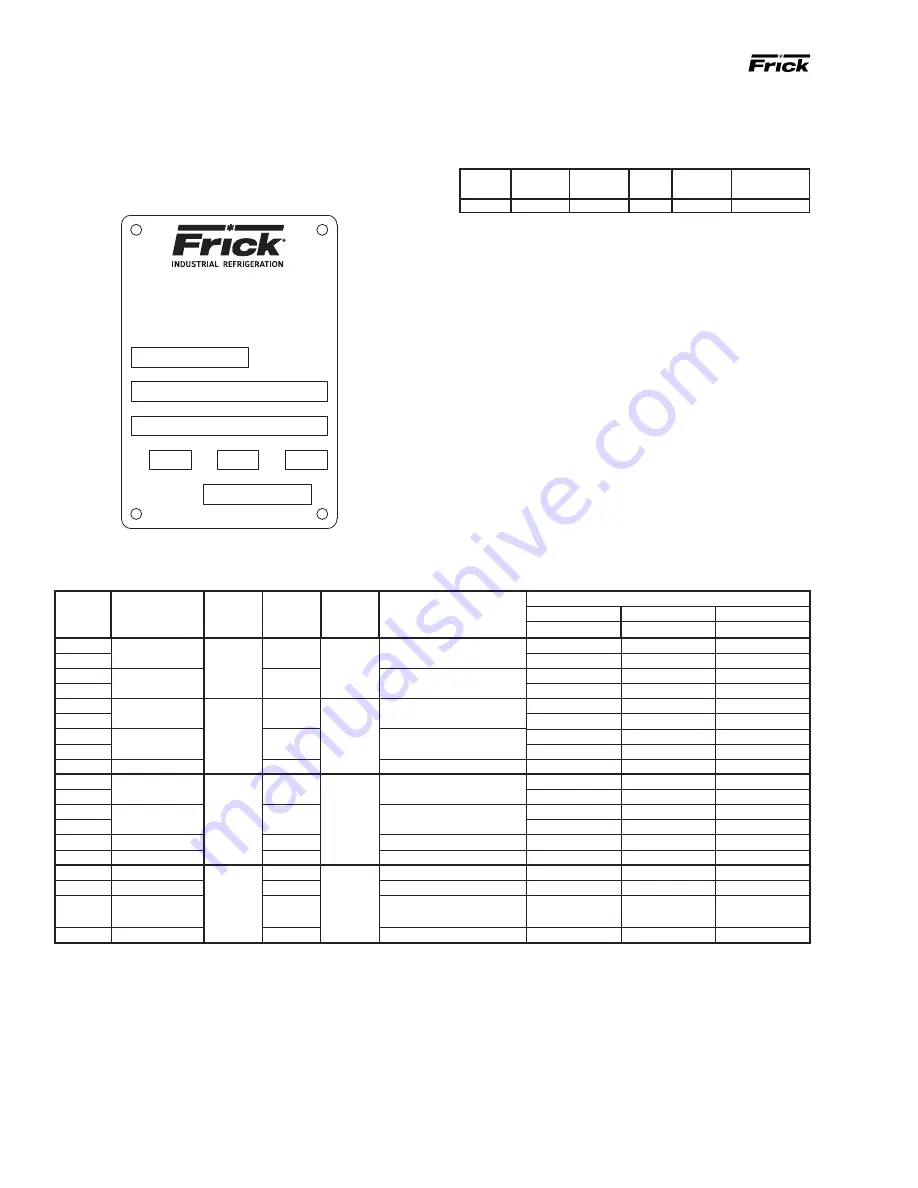

Compressor identification

Each compressor has an

identification data plate (see

below), containing compressor model and

serial number

mounted on the compressor body.

Figure 2: Compressor data plate

534B2722

COMPRESSOR SHAFT

CLOCKWISE ROTATION

534B2721

534B2720

534B2719

R22

COMPRESSOR OPERATES ON AND IS

COMPATIBLE WITH THE FOLLOWING

REFRIGERANTS

R290, R1270, NATURAL GAS

COMPRESSOR OPERATES ON AND IS

COMPATIBLE WITH THE FOLLOWING

REFRIGERANTS

R50, R134a, R170, R290, R404A, R410A, R507,

R513A, R600, R600A, R717, R728, R729, R744,

R1150, NATURAL GAS

COMPRESSOR OPERATES ON AND IS

COMPATIBLE WITH THE FOLLOWING

REFRIGERANTS

534C2934H01

SGXB2 4021

US2430125370500010

10241A89999999R

3600

600

41

USA

REFERENCE MATERIAL FIELD ON

SHEET 1 OF PRODUCTION ORDER

REFERENCE TABLE ON

SHEET 2 AND NOTE 3

REFERENCE TABLE

ON SHEET 2

REFERENCE TABLE ON

SHEET 2 AND NOTE 2

GENERATED BY SAP

ASSEMBLY PLANT LOCATION

534C2933H01

USA

US2430129999900010

10241A89999999R

100 CUMBERLAND VALLEY AVENUE

WAYNESBORO, PA 17268

ROTARY SCREW COMPRESSOR

MODEL NO.

MAX DRIVER SPEED

MAX ALLOWABLE PRESSURE

PART NO.

RPM

PSIG

BARG

ASSEMBLED IN

FROM FOREIGN AND DOMESTIC MATERIALS

SERIAL NO.

41

600

3600

SGXB2 4021

Rotary screw compressor serial numbers are defined by

the following information:

Example: 10240A90000015Z

Plant

Decade Month

Year Global

Additional

seq. no. remarks

1024

0

A

9

0000015 Z

Plant:

1024 = Waynesboro, 1153 = Monterrey

Month:

A = JAN, B = FEB, C = MAR, D = APR, E = MAY, F = JUN,

G = JUL, H = AUG, K = SEP, L = OCT, M = NOV, N = DEC.

Additional Remarks:

R = Remanufactured;

R1 = Rebuild;

R2 = Rebuild Plus;

Z = Deviation from standard configuration.

RWF II

model

Compressor

model

Rotor

diameter

Rotor

Max

speed

Geo. swept volume

drive shaft end

Displacement

4150 rpm

3550 rpm

2950 rpm

mm

L/d

rpm

ft³/ rev (m³/rev)

cfm (m³/h)

cfm (m³/h)

cfm (m³/h)

100

SGC 1913

193

1.35

4,500

0.16653 (0.00472)

-

591 (1,004)

491 (835)

119 SS

691 (1,174)

-

-

134

SGC 1918

1.8

0.22204 (0.00629)

-

788 (1,339)

655 (1,113)

159 SS

921 (1,566)

-

-

177

SGC 2313

233

1.35

4,500

0.29301 (0.00830)

-

1,040 (1,767)

864 (1,469)

209 SS

1,216 (2,066)

-

-

222

SGC 2317

1.7

0.36897 (0.01045)

-

1,310 (2,225)

1,088 (1,849)

264 SS

1,531 (2,602)

-

-

270

SGC 2321

2.1

0.45580 (0.01291)

-

1,618 (2,749)

1,345 (2,285)

316

SGC 2813

283

1.35

4,200

0.52501 (0.01487)

-

1,864 (3,167)

1,549 (2,631)

375 SS

2,179 (3,702)

-

-

399

SGC 2817

1.7

0.66113 (0.01872)

-

2,347 (3,988)

1,950 (3,314)

472 SS

2,744 (4,662)

-

-

480

SGC 2821

2.1

0.79546 (0.02253)

-

2,824 (4,798)

2,347 (3,987)

546

SGC 2824

2.4

0.90402 (0.02560)

-

3,209 (5,453)

2,667 (4,531)

496

SGCH/B 3511

355

1.1

3,600

0.82248 (0.02329)

-

2,920 (4,961)

2,426 (4,122)

676

SGCH/B 3515

1.5

1.12154 (0.03176)

-

3,981 (6,765)

3,309 (5,621)

856

SGCH/B 3519

SGXH/B 3519

1.9

1.42748 (0.04042)

-

5,068 (8,610)

4,211 (7,155)

1080

SGXH 3524

2.4

1.80328 (0.05106)

-

6,402 (10,876)

5,320 (9,038)

852

SGXH 4013

408

1.3

3,600

1.41180 (0.03998)

-

5,012 (8,515)

4,165 (7,076)

1179

SGXH 4018

1.8

1.95481 (0.05535)

-

6,940 (11,790)

5,767 (9,798)

1395

SGXH 4021

2.1

2.31320 (0.06550)

-

8,212 (13,952)

6,824 (11,594)

Note:

SS indicates a super speed model.

Table 1: Geometrical swept volume and displacement