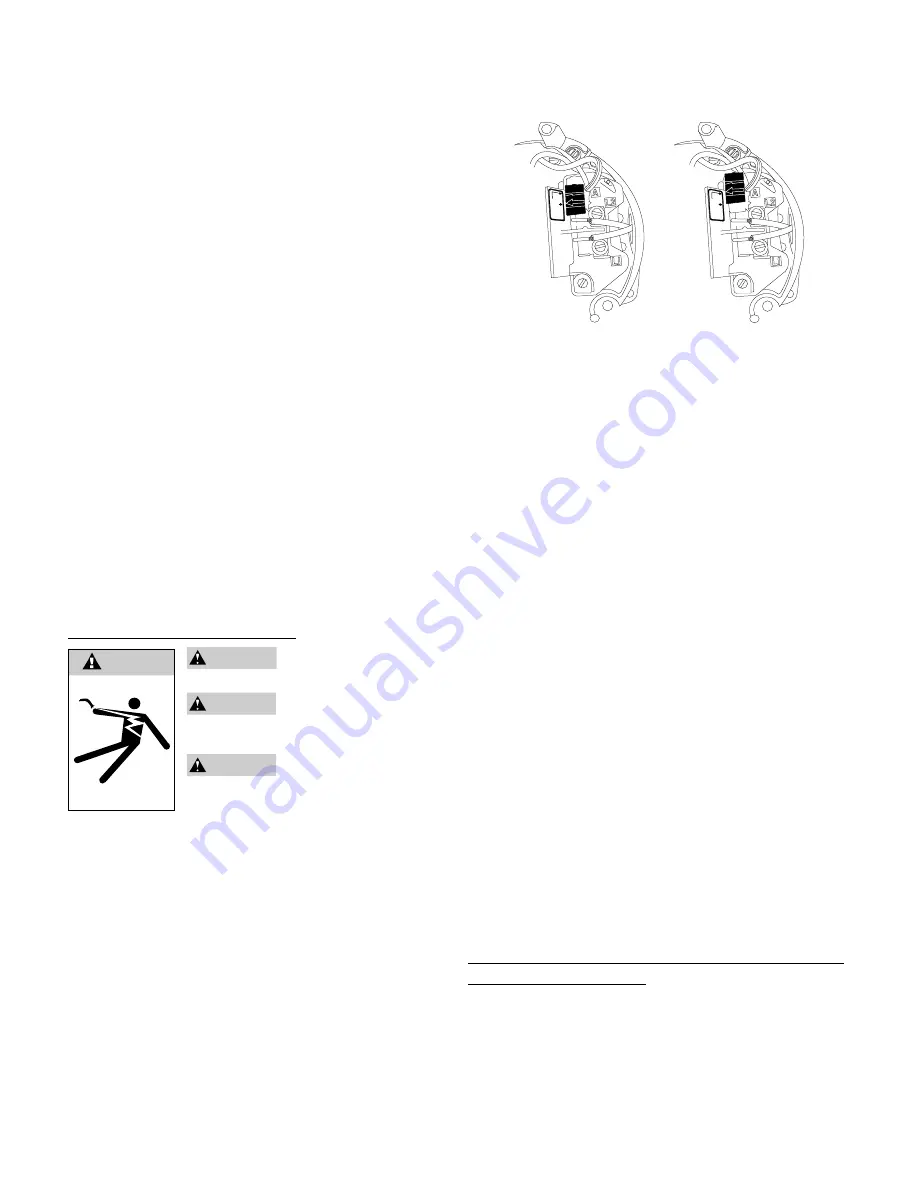

230V

115V

230V

115V

115V

230V

FIGURE 6

energize the pump, and you will have to re-prime the

system. Once the pump is turned on it may take several

minutes to remove all of the air from the system. On

installations with long suction piping, you may have to

add water several times to complete the priming process.

DEEP WELL PUMPS

Priming the pump means filling the pump, suction piping,

and drive water piping with water. Priming is completed

when you start the pump, and all the air is removed from

the piping system, but before you energize the pump you

must manually fill the pump and piping with water. Deep

well installations require a complete prime before starting

the pump. If you used one of the side discharge

connections on the pump, you can easily fill the pump

and piping with water through the 1” top port. If you

installed the control valve in the top discharge port, you

can prime the pump through the 1” priming hole in the top

of the valve. You will need to provide a priming tee if you

used the top discharge port but did not install the control

valve there. Fill the pump with water until full. All

horizontal offset piping should slope up from the well to

the pump to ensue that it is filled with water. Plug the

priming hole. Perform the “ADJUSTING THE CONTROL

VALVE” procedure listed below. Once the pump is

turned on it may take several minutes to remove all of the

air from the system. On installations with long suction

and drive water piping, you may have to add water

several times to complete the priming process.

ELECTRICAL INSTALLATION

WARNING

Hazardous voltage can

shock, burn or cause death.

CAUTION

If you are not sure of

proper electrical connections, consult a

licensed electrician.

CAUTION

Improper wiring can

result in permanent damage to the

motor. All electrical wiring should meet

the local electrical code.

NOTICE:

READ AND FOLLOW ALL INSTRUCTIONS!

Pump connection must comply with National Electric

Code (NEC) or Canadian Electric Code (CEC), and all

applicable local codes.

All dual voltage units come factory preset for 230

volts. (Figure 6)

Disconnect power at electrical panel before making any

electrical connections or changes.

Supply voltage must be +/- 10% of motor nameplate

voltage. Low or high voltage can damage the motor and

will void the warranty.

If possible, connect pump to dedicated branch circuit with

no other appliances on it.

Do not operate pump unless pump is grounded.

VOLTAGE CHANGE

NOTE:

To change the motor voltage(Figure 6) unplug the

dual voltage plug on the motor and reconnect it in the

position required to match the supply voltage. The motor

can be set for 115 volts or 230 volts. The voltage setting

of the motor can be determined by looking at the

alignment of the arrow on the plug and the arrow on the

motor terminal board (located under the motor’s end

cover). Any questions as to which voltage setting is

required for proper motor and pump operation in your

system should be directed to an electrical professional.

The factory preset is 230 volts.

NOTICE:

Check motor terminal cover or nameplate for

wiring instructions. The essential pump motor facts are as

follows:

1. 3450 RPM

2. Single Phase

3. Dual Voltage, 115/230

4. 1/2, 3/4, 1, and 1-1/2 Horsepower motors are wired for

230 volts as a factory standard.

NOTE: All wiring is subject to official inspection and must

conform to the local electrical code. Install a circuit

breaker or fused disconnect switch near the pump.

Remove the cover from the pressure switch. Connect the

incoming power wires to the LINE terminals and the

green or bare wire to the ground screw, then ground the

entire unit. Refer to

FIGURE 7 for internal sketch of

pressure switch.

CONTROL VALVE ADJUSTMENT (DEEP WELL

INSTALLATION ONLY)

A control valve is required for all deep well installations.

At system start-up, this valve will need to be adjusted as

described below to assure optimum performance.

1. Install a pressure gauge that reads pressure at the

pump case.

2. Open several faucets downstream from the

control valve.

WARNING