Manual - Formech 450DT V1.0 - 0317

17

Operating Techniques

Heaters

The powerful quartz heaters are designed to heat the plastic rapidly without burning the surface. The time

required to heat the plastic sheet remains fairly constant once the heaters have reached their operating

temperature.

Heating cycle times vary according to a number of factors. With a little experience, timings may be easily

estimated.

Some plastics such as styrene have a wide tolerance to heating times giving consistently good mouldings.

Care must be taken with other materials such as ABS, as the surface will blister if the temperature limit is

exceeded. Such plastics may also require drying prior to thermoforming.

The moulding should be formed when the plastic is suffi ciently relaxed to become indented by the blunt end

of a pencil but not soft enough to sag.

A properly heated sheet will give an excellently defi ned moulding. If the sheet is not hot enough while

forming the moulding will not pick up all the detail from the tool.

The times below were recorded using styrene at an ambient temperature of 20 degrees C

With the machine at operating temperature. Please note that these times are a guide only.

Various factors will affect the heating time including the colour and surface fi nish of the material.

1.5mm Thick = 60 seconds

2.0mm Thick = 95 seconds

4.0mm Thick = 240 seconds

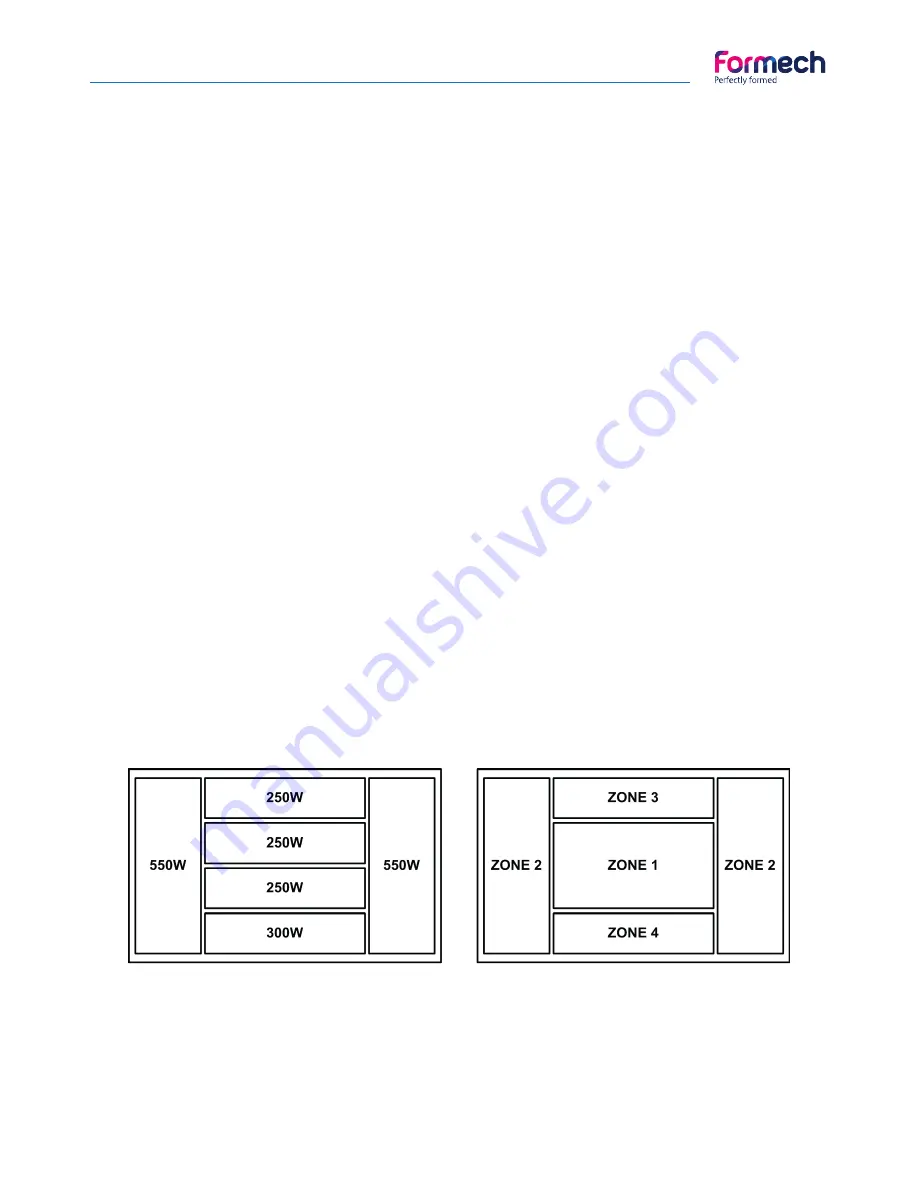

The Heater elements are confi gured so that the front and side areas are slightly higher powered than the

central and rear area. This is to provide more heat around the outside edges of the forming area which can

be affected by environmental factors such as draughts. The element and zone layouts are shown below.

Front

Front