Part IV: Maintaining The Wood Chipper

Belt Tension

The tension of the belts should be checked before each use. Additionally when the machine

is new or after the belts have been replaced, the tension should be checked after the first 15

minutes of use as new belts will stretch.

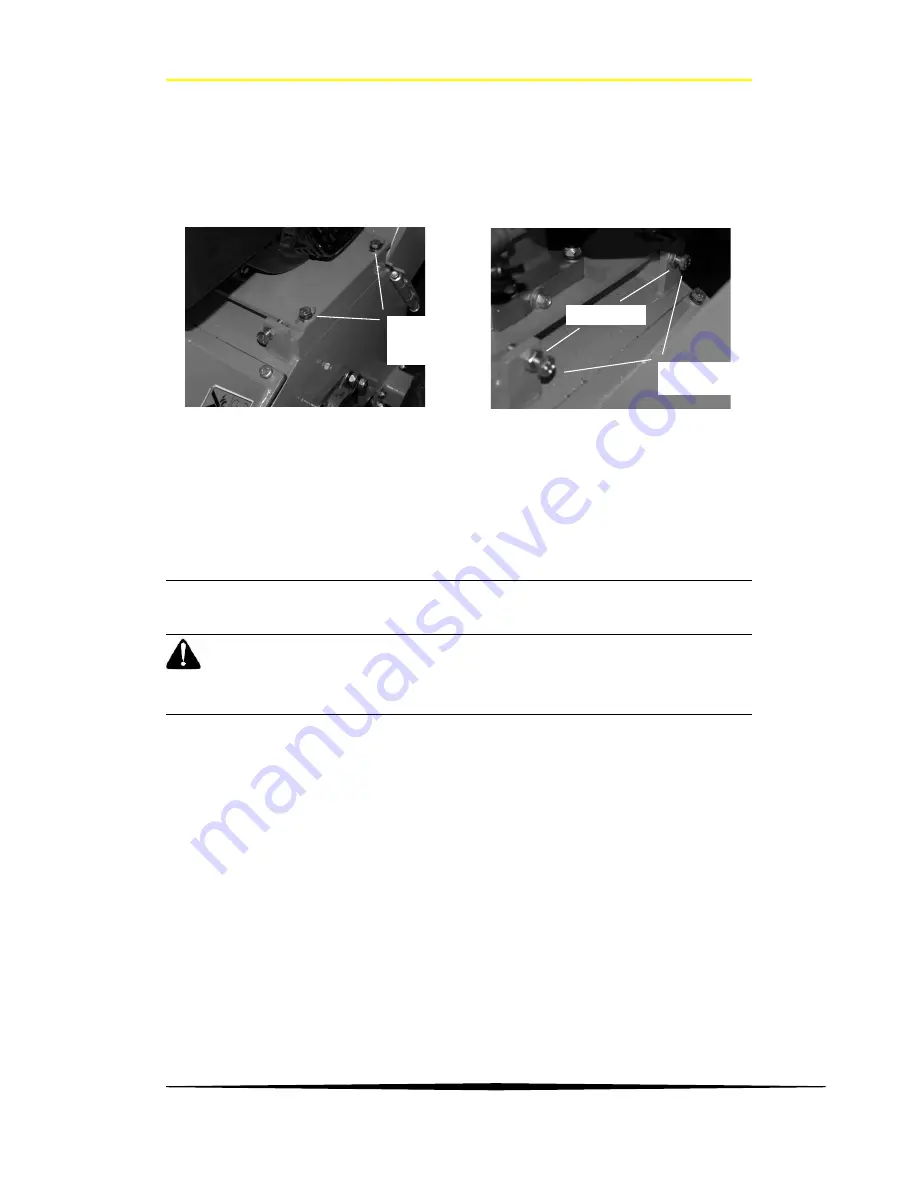

To adjust the tension, loosen the four mounting bolts that secure the engine plate to the

chipper. The plate can then by moved backwards or forwards using the two adjusting bolts.

To adjust the bolts, loosen the lock nuts then move the adjusting bolts backwards or

forwards the required amount. Once the adjustment is correct, tighten the lock nuts. You

should be careful to adjust each bolt by the same amount. Finally, re-tighten the four

mounting bolts.

Lubrication

NOTICE

All Bearings of your Chipper are sealed units and should have sufficient lubricant to last the

life of your machine with normal use.

Removing the Blades

To remove the blades for sharpening, you will need a 17mm socket with no inner taper, as

the bolt heads are shallow. If a socket with inner taper is used, there is a possibility of

rounding the bolt head as the socket will slip.

When refitting the blades, you should use a small amount of mild thread lock to secure each

bolt.

12

Mounting

bolts, 2 each

side of plate

Adjusting

bolts

Lock nuts