A-1

Appendix A

Explanation of Test Report

Explanation of Test Report

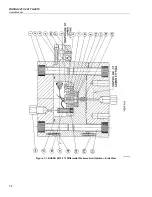

When the RUSKA Differential Pressure Null Transducer is operated at an elevated

pressure, the body is in a state of temporary strain. Even though the pressure on each side

of the diaphragm may be equal, as they are when the two cavities are connected together,

the output display meter indicates that a difference in pressure does exist. This erroneous

indication is caused by a displacement of the transformer with respect to the diaphragm

and is a result of the strain in the body. Since the position of the diaphragm is of great

interest when making PVT experiments, the value of the change must be determined by

calibration. The reported result of the calibration is the apparent change in the original

setting of the zero-adjusting potentiometer as a function of the pressure within the

transducer.

In practice, after the necessary proof-pressure and leak tests have been completed, a

common gas pressure is applied to both sides of the diaphragm. As the pressure is

increased in uniform increments, the output meter is restored to its null position by

adjustment of the zero potentiometer. The value of the counter-type dial on the

zero-adjusting knob is recorded for each increment. The difference in these values and

that of the original zero is plotted against their corresponding internal pressures and a

smooth curve is fitted to the set of points. Unless otherwise stated on the report, the curve

represents values observed at the maximum gain of the indicating circuit. Negative values

for the abscissae imply that the observed readings of the dial are less than that of the

original zero. Curves are constructed for both increasing and decreasing internal

pressures.

In use, it is necessary to determine from the curve, the change in dial setting for the

pressure at which the cell has become stable, subtract this number from that observed

when the cell was exposed to the atmosphere, and set the dial to the new figure. When the

two mediae are balanced, the diaphragm will be in its original position, and the pressure

across it will be zero.

The gain of the electronic circuit is such that, on an average, a displacement of the

diaphragm of 0.75 microinch is equivalent to one unit indicating meter. This information

is of use in making an error analysis of the measurement process.

The shift in the zero position of the diaphragm as a result of alternate overranging

pressures is obtained by pressurizing one side of the diaphragm to 2000 psi or so for a

few minutes. The pressure is then released and the transducer allowed time to recover.

After setting the meter to null, the opposite side of the diaphragm is pressurized by the

same amount. Upon release of the latter pressure and recovery of the transducer, a small

Содержание RUSKA 2413

Страница 6: ...RUSKA 2413 2417 2416 Users Manual iv ...

Страница 8: ...RUSKA 2413 2417 2416 Users Manual vi ...

Страница 26: ...RUSKA 2413 2417 2416 Users Manual 6 6 ...

Страница 34: ...RUSKA 2413 2417 2416 Users Manual 8 2 ...

Страница 36: ...RUSKA 2413 2417 2416 Users Manual 9 2 ...