12-7

Troubleshooting Guardian II Metal Bellows Seals

Failure

Probable Cause

Corrective Action

Leakage through

1. Insufficient compression of bonnet

1. Tighten bonnet flange bolting until

bellows assembly

gasket

leakage stops

gasket

2. Worn or defective bonnet gasket

2. Disassemble and replace bonnet gasket

Leakage through

1. Failure of metal bellows seal

1. Disassemble and replace metal bellows

packing box or

assembly

seal assembly and all gaskets

“tell-tale” tap

Valve does not

1. Loose stem locknut on bellows stem

1. Disassemble, tighten stem locknut

seat or seats

2. Improper actuator stem

2. Correct stem engagement (refer to steps

too early

engagement

9 thru 12 in the “Reassembly” section)

Leakage through

1. Insufficient compression of gaskets

1. Tighten bonnet flange bolting until

bellows assembly

leakage stops

gasket

2. Worn or defective housing, bellows

2. Disassemble and replace all gaskets,

assembly or seat ring gasket

including seat ring gasket

then tighten the bolt directly opposite

1

/

6

-turn and

so on around the flange. Firmly tighten all bolts

evenly and completely to compress the bonnet

gasket and to seat the bonnet. Torque the bonnet

bolts to the suggested torque values in Table I.

14. Apply air over the piston to seat the plug. For all

throttling valves, adjust the stem clamp so that with

full instrument signal to the positioner the full signal

scribe line on the positioner cam points to the

center of the cam roller bearing.

Tighten the stem clamp bolting. Proper tightness is

important since this adjustment secures the actuator

stem to the bellows stem. Adjust the stroke plate so

that the stem clamp points to the “closed” position.

15. If the valve has been taken out of the line, make

sure the flow arrow indicates proper flow direction

upon reinstallation.

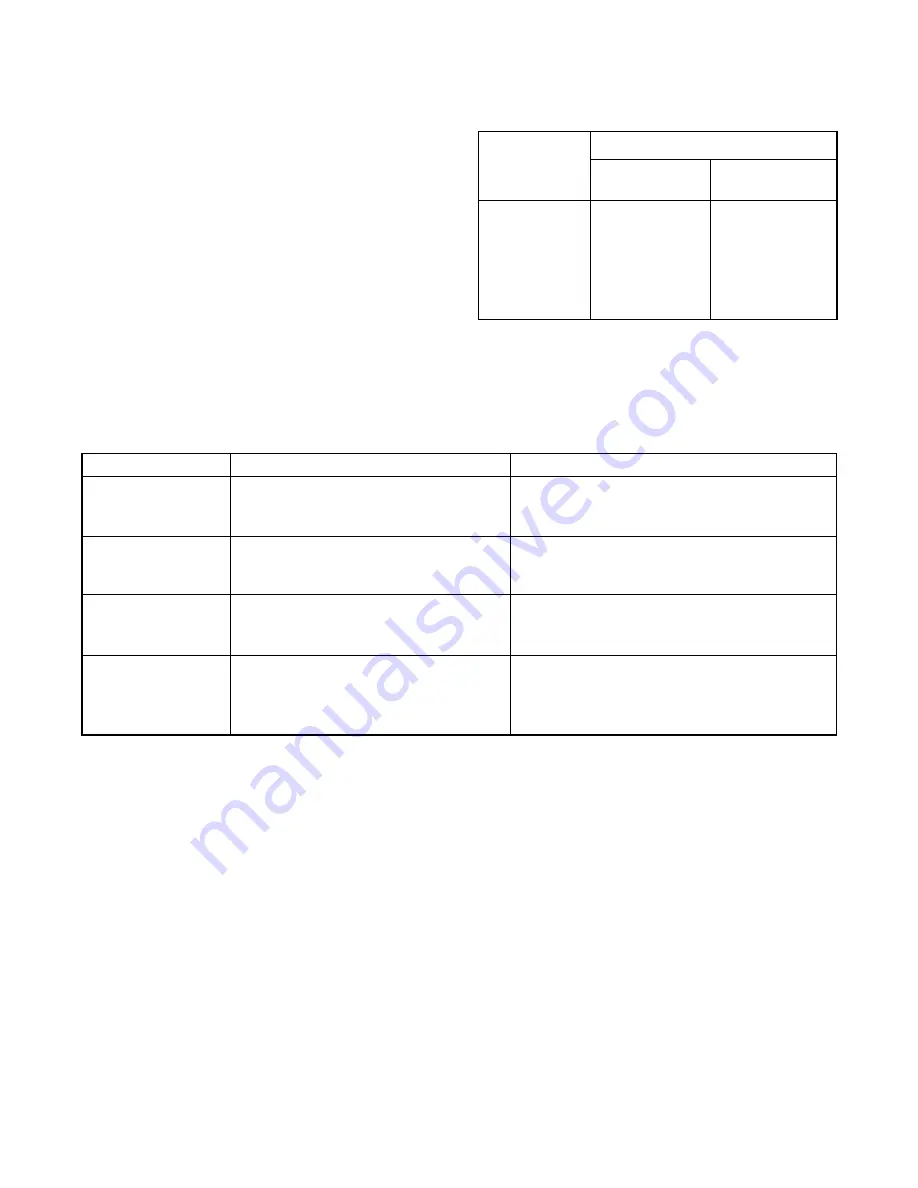

Table I: Suggested Bonnet Bolting

Torque Values (ft-lbs, +10 percent)

Bolt/Stud Material

Bolt

Size

Carbon

Stainless

(inches)

Steel

Steel

5

/

8

80

50

3

/

4

140

90

1

350

220

1

1

/

8

510

330

1

1

/

4

730

460

1

3

/

8

990

630

3. Loosen the actuator stem clamp.

4. Remove the packing box bolting.

5. Remove the yoke clamps.

6. Remove the actuator by turning it completely off

the bellows seal bonnet and bellows seal stem.

CAUTION: Although the valve incorporates an

anti-rotation pin, care should be taken not to

put excessive torque on the plug stem/bellows

assembly. Excessive torque can damage bel-

lows and/or shear the anti-rotation pin.

7. Remove the bolting from the upper housing clamps

or flanges.

WARNING: If there has been a bellows failure,

process fluid may be trapped in the bellows

seal bonnet; therefore, be extremely cautious

when removing the upper housing bolting.

FORMED METAL BELLOWS SEAL

Disassembling Formed Metal Bellows Seal

To disassemble the formed metal bellows seal, refer to

Figures 4 and 5 and proceed as follows:

WARNING: Depressurize line to atmospheric pres-

sure, drain all process fluids and decontaminate

the valve (if toxic or hazardous materials are

present). Failure to do so can cause serious injury.

1. Remove the bonnet flange bolts or nuts.

2. Remove the entire actuator/bellows seal assem-

bly, plus the bonnet and plug, by lifting them

straight out of the body.

CAUTION: Heavy assemblies may require a

hoist. A lifting ring is provided on most actua-

tors for this purpose; otherwise, lift by the yoke

legs using lifting straps and the hoist.