12-11

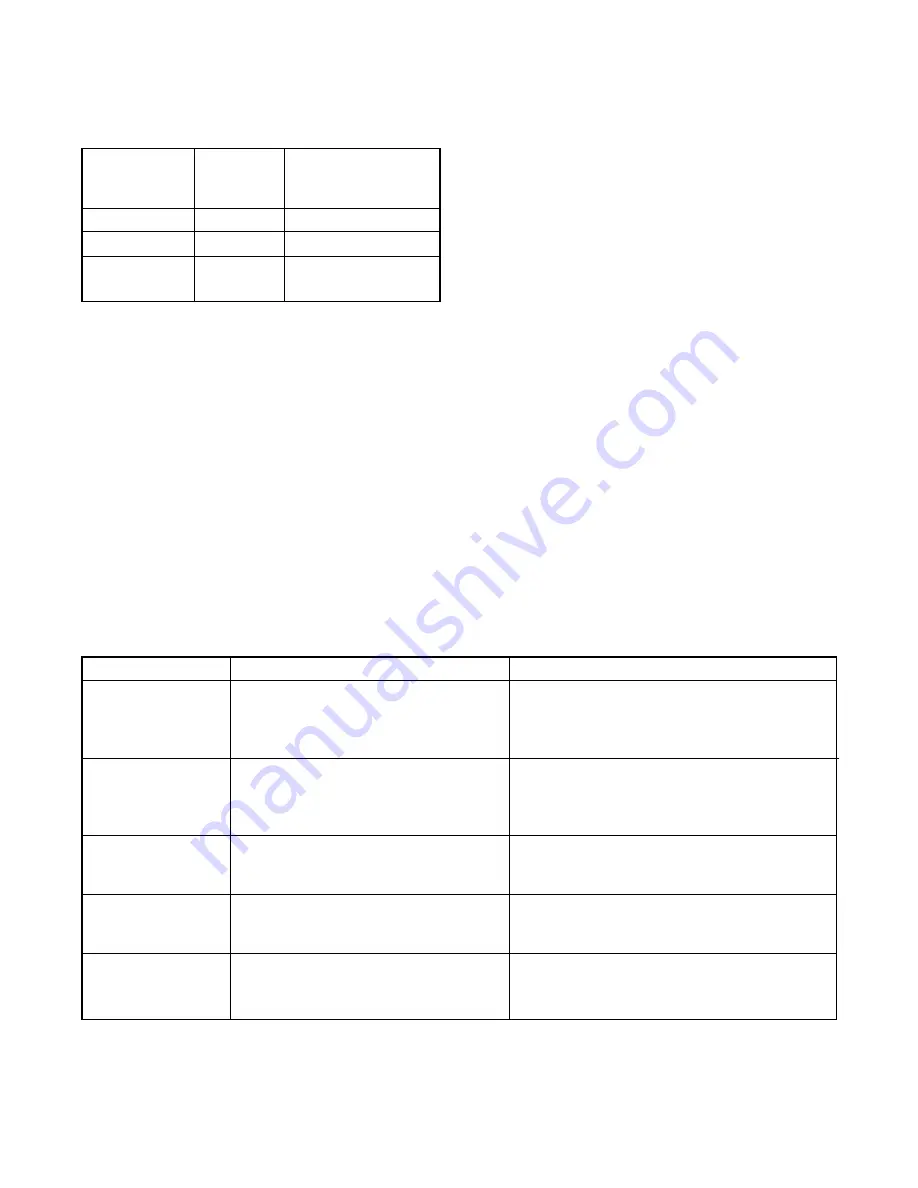

Table II:

Extended Plug to Bonnet Dimensions

(refer to Figure 5)

Valve Size

Stroke

Distance Between

(inches)

(inches)

Extended Plug

and Bonnet

1

/

2

,

3

/

4

, 1

1.00

1.03

1

1

/

2

, 2

1.50

1.56

3, 4, 6

2.50

2.56

(class 150)

19. Install the entire actuator/bellows seal subassem-

bly into the valve body. Tighten the bonnet flange

bolting finger-tight.

20. Apply air pressure over the piston while exhausting

the other side to seat the valve. Tighten two

opposing bonnet flange bolts or nuts

1

/

6

- turn (one

flat). Tighten each bonnet bolt in this manner until

the bonnet bottoms metal-to-metal in the body.

This can easily be felt through the wrench.

21. Release the air in the cylinder. Firmly tighten the

upper and lower housing clamps or flanges by

tightening two opposing bolts, so that even pres-

sure on the gasket and proper alignment of the

housing and body bonnet are maintained.

22. Adjust the stem clamp to the correct position ac-

cording to the air action (air-to-open valves should

be adjusted so that the stem clamp points to

“closed” on the stroke indicator plate; air-to-close

valves should point to “open”).

23. Attach the packing box bolting and tighten the

packing box nuts to slightly over finger-tight.

CAUTION: Do not overtighten packing. This

can cause excessive packing wear and stem

friction which may impede stem movement.

24. Stroke the valve and check for smooth operation.

Troubleshooting Formed Metal Bellows Seals

Failure

Probable Cause

Corrective Action

Leakage through

1. Insufficient compression of housing

1. Tighten flanges or clamps until leakage

lower housing

gasket

stops

clamps or flanges

2. Worn or defective lower housing

2. Disassemble and replace lower housing

gasket

gasket

Leakage through

1. Insufficient compression of seal ring

1. Tighten flanges or clamps until leakage

upper housing

gaskets

stops

clamps or flanges

2. Worn or defective upper seal ring

2. Disassemble and replace upper seal

gaskets

ring gaskets

Leakage through

1. Insufficient compression of bonnet

1. Tighten bonnet flange bolting until

bonnet gasket

gasket

leakage stops

2. Worn or defective bonnet gasket

2. Disassemble and replace bonnet gasket

Leakage through

1. Failure of metal bellows seal

1. Disassemble and replace metal bellows

packing box or

assembly

seal assembly and all gaskets

“tell-tale” tap

Valve does not

1. Loose stem locknut on plug stem

1. Disassemble, tighten stem locknut

seat or seats

2. Improper actuator stem

2. Correct stem engagement (refer to steps

too early

engagement

15 and 16 in the “Reassembly” section)

16. For correct stem engagement on air-to-close valves,

a check valve must be used to lock air into the top

of the actuator. This puts the actuator stem in the

extended position. Turn the actuator stem onto the

bellows seal stem until about

1

/

16

-inch of space is

left between the bottom of the yoke and the shoul-

der of the bellows seal bonnet. Carefully exhaust

the check valve and the yoke will come into contact

with the bonnet. This will provide the proper clear-

ance between the piston and the top of the yoke.

17. Attach the yoke clamps.

18. Using new seat and bonnet gaskets, replace the

seat ring and seat retainer in the body.