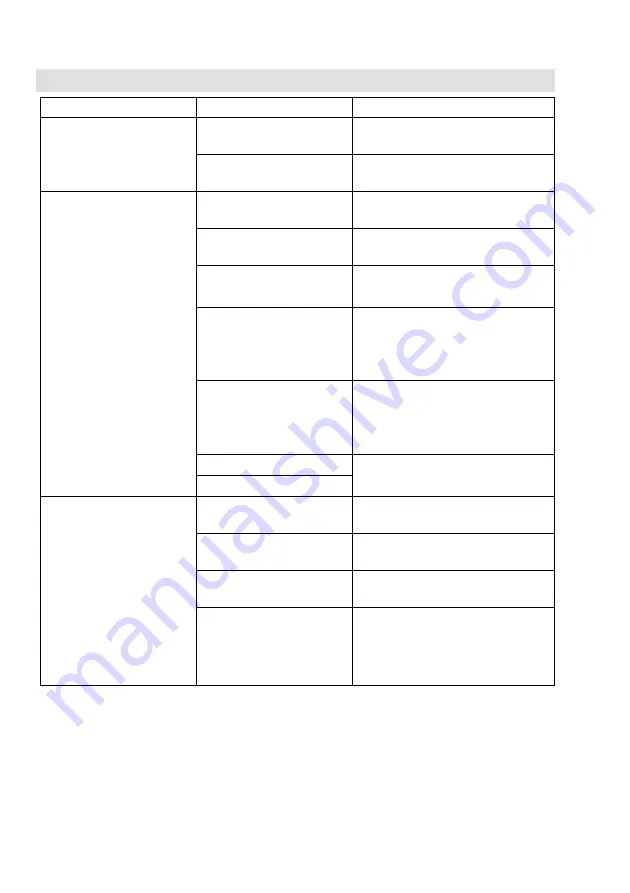

Troubleshooting

Problem Cause Remedy

Insufficient flowrate

The equipment is not

completely open.

Completely open the equipment

The sealing plugs have not

been removed.

Remove the equipment. Take off the

sealing plugs. Mount the equipment.

Fluid escapes (equipment is

leaking).

The end connections are not

tight.

Insulate the connections.

A gasket on the body is

defective.

Replace the equipment with a new one.

Leakage occurs at the stem,

the bellows is damaged.

Re-tighten the stuffing box packing.

Replace the equipment with a new one.

The body has been damaged

by corrosion or erosion.

Check the resistance of the material for

the fluid used.

Use a device made from a material that

is suitable for the fluid used.

The equipment has been

damaged by frost.

Replace the equipment with a new one.

When shutting down the installation

make sure that all lines and the

equipment are completely drained.

The plug or seat is damaged.

Replace the equipment with a new one.

The seat is leaking.

Excessive force is needed to

turn the handwheel.

The locking screw has been

tightened.

Loosen the locking screw.

The position of the stroke

limiter is fixed by a locknut.

Loosen the locknut of the stroke limiter.

The stem is insufficiently

lubricated.

Apply lubricant to the stem.

Limit stop has been reached.

You can only turn the handwheel up to

the stop.

Turn the handwheel into the other

direction.

If faults occur that are not listed above or cannot

be corrected, please contact our Technical

Service or authorized agency in your country.

16