ERPN-M USER INSTRUCTIONS ENGLISH 02-08

Page 14 of 37

3.3.3.3 Semi open impeller

The pump casing is equipped with a renewable wear

plate.The axial thrust is balanced by back vanes.

3.3.3.4 Inducer

All different impellers can be optionally equipped with

an inducer for low NPSHA applications.

3.3.4 Magnetic Coupling

The magnetic coupling consists of:

a) The

Can:

This is the actual sealing element of the magnetic

coupling. The driving torque is transmitted via the

can due to the magnetic field between the inner

and outer rotors.

b) Outer

Rotor:

The outer rotor driven by the pump shaft and

holds the set of magnets needed to meet the

torque requirement.

c) Inner

Rotor:

The inner rotor drives the impeller. Fluid

lubricated Silicon Carbide bearings take all the

hydraulic forces.

d) Secondary

Seal:

As required by API 685 a secondary seal is used

to avoid leakage to the atmosphere in case of

magnetic coupling failure.

e) Temperature

Sensor:

It observes the temperature at the Can surface to

ensure that the Silicon Carbide bearings are

flushed properly.

3.4 Performance and operating limits

In the interest of operator safety

the unit must not be operated above the nameplate

conditions. Such operation could result in unit failure

causing injury to operating personnel. Consult

instruction book for correct operation and

maintenance of the pump and its supporting

components.

4.0 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations, see section 1.6.4,

Products used in

potentially explosive atmospheres.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Refer to the general arrangement drawing for the

pump set.

4.2 Part Assemblies

The pumps are delivered completely mounted and

prealigned with the motor. Also the shaft seal is in the

correct position. Final alignment after complete

installation is necessary. If drivers and/or seal systems

are delivered separately, follow the assembly

procedure in section 6.8.

4.3 Foundation

The foundation shall be located on a place that allows

a minimum of pipe work and that is easily accessible

for inspection during operation. According to the

environment the foundation may consist of concrete

or of steel. It must be rigid and heavy enough to

absorb normal vibrations and shocks.

4.3.1 Horizontal alignment of the baseplate

Horizontal alignment is done with levelling screws.

Use a spirit level for correct horizontal alignment of

the baseplate.

The max. misalignment is 0.5 mm/m

baseplate length.

4.3.2 Steel foundation

When the pump unit is mounted directly on structural

steel frame, it shall be well supported by constructural

beams. It is recommended to check the natural

frequency of the steel frame, because it shall not

coincide with the pump speed. The exact horizontal

alignment is very important!

Ensure that the base plate is

leveled horizontally to 0.5 mm/m. To avoid any

distortion of put shims under the base plate before

bolting it down to the steel frame. Welding of the base

plate to the steel frame is not recommended because

of possible distortion of the same.

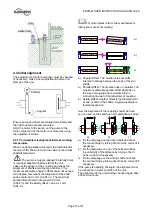

4.3.3 Concrete foundation

A concrete foundation must have an exact horizontal

alignment and must be placed on solid ground. First a

basic foundation shall be built with square shaped

holes for embedding the foundation bolts. After

putting the base plate into the foundation the proper

alignment can be obtained by adjusting it with shims

under the base plate. Now insert the foundation bolts

and grout the space between the basic foundation

and the base plate with grouting cement (refer to

illustration)

It is very helpful to use a properly made and stable

wooden frame around the base plate. So the grouting

cement will not flow side. When the grouting is totally

set and hardened the foundation bolts shall be

tightened in a firm and symmetrical way.