Step Five

Step Six

INSTALLATION

ELECTRICAL

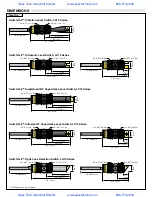

Through Wall Installation:

Flowline’s Switch-Tek™ level switches may be installed through the

top, side or bottom of a tank wall. The sensor has male 3/4" NPT

threads on either side of a 15/16" wrench flat. This enables the user to

select the sensor’s mounting orientation, installed outside of the tank

in, or inside of the tank out.

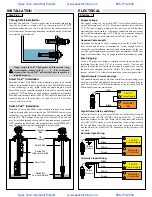

Supply Voltage:

The supply voltage to the Switch-Tek™ level switch should never

exceed a maximum of 36 VDC. Flowline controllers have a built-in

13.5 VDC power supply which provides power to all of Flowline’s

electrically powered sensors. Alternative controllers and power sup-

plies, with a minimum output of 12 VDC up to a maximum output of

36 VDC, may also be used with the Switch-Tek™ level switch.

Required Cable Length:

Determine the length of cable required between the Switch-Tek™

level switch and its point of termination. Allow enough slack to

ensure the easy installation, removal and/or maintenance of the sen-

sor. The cable length may be extended up to a maximum of 1000 feet,

using a well-insulated, 14 to 20 gauge shielded four conductor cable.

Wire Stripping:

Using a 10 gauge wire stripper, carefully remove the outer layer of

insulation from the last 1-1/4" of the sensor's cable. Unwrap and

discard the exposed foil shield from around the signal wires, leaving

the drain wire attached if desired. With a 20 gauge wire stripper,

remove the last 1/4" of the colored insulation from the signal wires.

Signal Outputs (Current sensing):

The standard method used by Flowline controllers; this technology uses

only two wires (Red and Black). The sensor draws 5 mA when it is dry,

and 19 mA when wet. NC/NO status must be set by the controller. The

White and Green wires are not used.

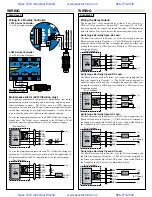

Smart Trak™ Installation:

Flowline’s Smart Trak LM10 series mounting system is an in-tank

fitting which enables users to install up to four FLOWLINE sensors

of any technology, to any depth, along the entire length of track.

Smart Trak may be installed through the top wall of any tank using a

standard 2" NPT tank adapter. If no tank top installation is available,

Flowline's side mount bracket, LM50-1001, enables Smart Trak to be

installed directly to the side wall of a tank.

Do not use PFA Teflon

sensors with Smart-Trak.

Switch Pak™ Installation:

Flowline’s Switch Pak LM45 series mounting system is an in-tank

fitting which enables users to install one FLOWLINE sensor, of any

technology, to a specific depth. The Flowline sensor may be installed

onto the 3/4" NPT adapter at the end of the Switch Pak. Switch Pak

may be installed through the top wall of any tank using a standard 2"

NPT tank adapter. Flowline's side mount bracket, model LM50-1001,

may also be used if top wall installation is not available.

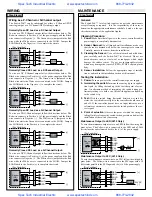

Signal Output (Relay switching):

Allows the sensor to switch a small load on or off directly, using an

internal 1A relay (60 VAC/60 VDC). Only model LU10-___5 uses the

relay and features 4 wires (red, black, white and green) and a shield

wire. The NO/NC status is set by the polarity of the voltage feeding

the red and black wires. The green wire is the common for the relay

and the white wire is the NO or NC, depending on the polarity of red

and black.

Switch-Tek

High Level Switch

Switch Pak

LC06

Junction

Box

Switch-Tek

Low Level Switch

1/2

Coupling

Smart Trak

Red

Black

Shield

Ground

24 VDC

Power Supply

+

-

Multimeter

(Continuity)

-

+

White

Green

Red

24 VDC

Power Supply

+

-

Multimeter

(mA)

-

+

Black

Always install the 3/4” Viton gasket with the metric (long

sensor length) versions of the L___-__2_. The G threaded

version of the Switch-Tek™ will not seal unless the gasket is

installed properly.

Normally Open Wiring:

Normally Closed Wiring:

Black

Red

Shield

Ground

24 VDC

Power Supply

+

-

Multimeter

(Continuity)

-

+

White

Green

Spec Tech Industrial Electric www.spectechind.com

888-773-2832

Spec Tech Industrial Electric www.spectechind.com

888-773-2832