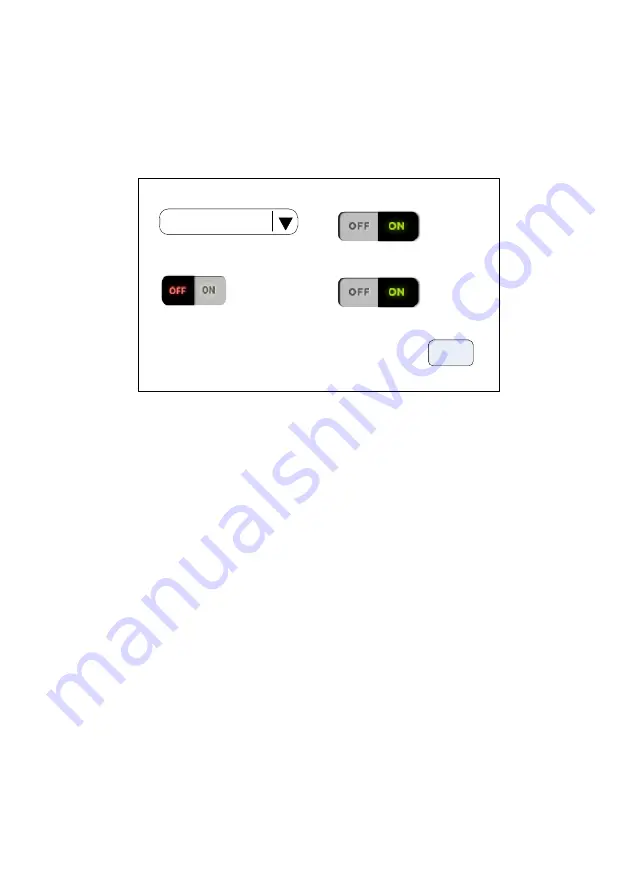

4.6 External Setting Interface

External Setting Interface as below:

Pulse

OK

External Control Signal

Ext.Start/Stop

Ext.CW/CCW

Foot Pedal Setting

Click

System

Settings

button in the main interface, then click

External Control

to

enter

External Settings

interface.

a.

There are two types of signals for external control motor start/stop and

direction

:

Level mode and Pulse mode

. Connection interface refers to the

external control interface instruction.

b.

Various external control modes are independently set on switches, which

will only work after the corresponding external control function is turned

on.