F

L

O

M

A

G

3

0

0

0

-

In

st

al

la

tio

n

a

nd

O

p

er

at

io

n

M

an

ua

l

3

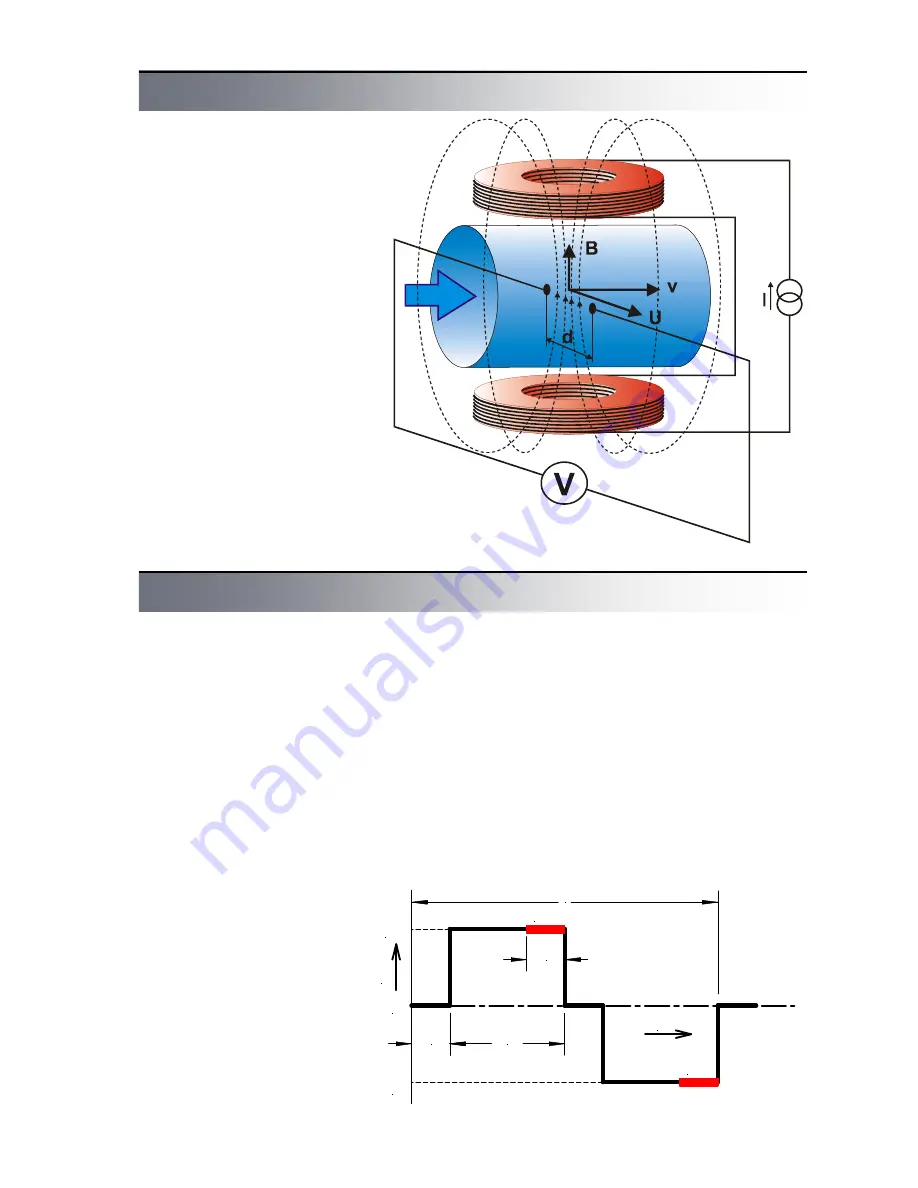

An magnetic flowmeter is used

for volume flow measurement of

electrically conductive liquids.

Measurement principle is based

on Faraday law on electromag-

netic induction. A sensor con-

sists of a non-magnetic tube

with non-conductive lining,

measuring electrodes and two

coils generating electromag-

netic field. Flowing liquid forms

a conductor. Magnetic field in-

duces voltage

U

in this conduc-

tor that is proportional to mag-

netic induction

B

, distance be-

tween electrodes

d

and flow

velocity

v

.

U = B x d x v

As magnetic induction and dis-

tance between electrodes are

constant, induced voltage is

proportional to velocity of liquid

flow in the tube. Volume flow

rate is product of flow velocity

and tube cross section.

Q = v x S

Fig.1 - Principle of measurement

Principle of measurement

Technical solution

The magnetic flowmeter itself

consists of two basic parts – a

flow sensor and a converter.

The converter can be either an

integral part of the sensor

(compact version) or separated,

connected with the sensor us-

ing a cable (remote version).

The sensor consists of a non-

magnetic tube with non-

conductive lining, measuring

electrodes, excitation coils and

cables. There are various sen-

sor versions available enabling

connection to adjacent tubes

with flanges (type

P

) and fittings

(gas fitting type

G

or food indus-

try fitting type

V

) or wafer which

are installed between flanges

using clamps (type

B

). Non-

conductive lining can be made

of technical rubber (types

TG

,

MG

or

NG

) or Teflon (type

T

).

The converter is used for gener-

ating excitation current in coils,

processing of signal from meas-

uring electrodes, displaying of

measured data and generating

output signals. Current in exci-

tation coils has constant value

250 mA or 125 mA and is pulse

generated with alternating po-

larity to avoid permanent mag-

netization of the sensor. Excita-

tion pulse frequency can be

chosen from six values – 25 Hz,

12,5 Hz, 8,33 Hz, 6,25 Hz,

3,125 Hz and 1,56 Hz. Excita-

tion current of 250 mA with ex-

citation frequency 3,125 Hz is

suitable for all standard applica-

tions. Other settings can be

used for specific applications.

Excitation current and fre-

quency are factory set before

sensor calibration and their later

modifications are not allowed.

Voltage induced in measuring

electrodes is measured always

on the end of excitation pulse

when magnetic field is steady.

Each excitation pulse is fol-

lowed by refreshing period. Sig-

nal processing and parameter

setting are performed digitally

and the converter contains no

setting controls or other moving

parts what ensures its high reli-

ability and long-term stability.

T

t

I

+I

-I

m

m

1/8T

3/8T

1/8T

0

Fig. 2 - Excitation pulse form