F

L

O

M

A

G

3

0

0

0

-

In

st

al

la

tio

n

a

nd

O

p

er

at

io

n

M

an

ua

l

12

Parameter setting

The magnetic flowmeter con-

verter can be configured in two

ways, as required: either using

a PC connected via serial inter-

face, or using keys.

Press

4

to switch the display

to programming mode. Pro-

gramming mode is password

protected against unauthorized

access. Correct password (4-

digit number) must be entered

to obtain access to main menu.

Password of a new instrument

is always set to 0000.

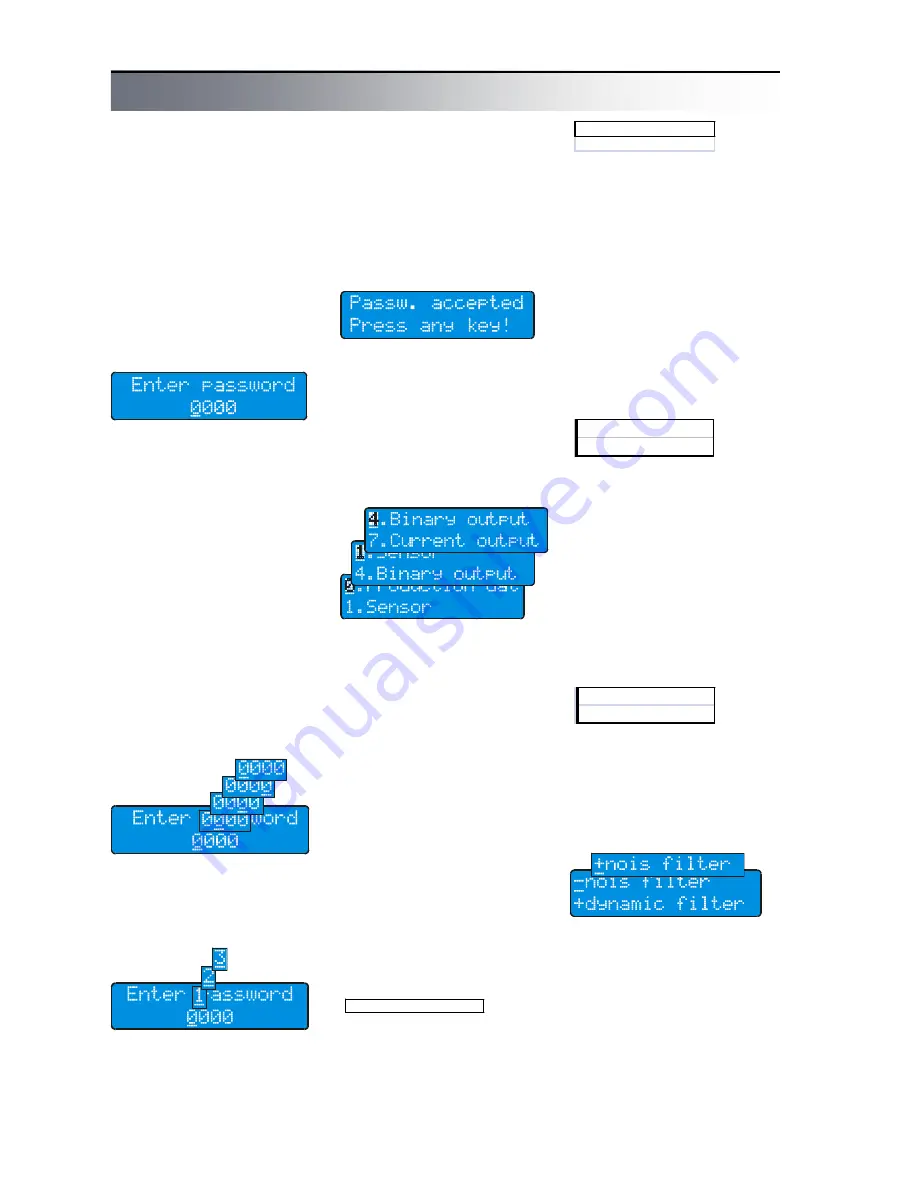

Fig. Enter password

This is also initial value dis-

played as default. Simply con-

firm it to enter in menu.

Password can be changed as

required before you leave the

programming mode.

Warning! You can switch the

instrument to data display mode

anytime by pressing

1

and

check current parameter set-

tings. However, the instrument

is not password protected

against unauthorized access

until you enter EXIT command.

Programming runs in back-

ground and with only a few ex-

ceptions has no influence to

measurement.

Fig. Cursor movement

2

key moves cursor to the

right. When the utmost right

position is reached, the cursor

returns to the left.

Fig. Character changing

system returns to the first avail-

able character.

Character set is always se-

lected with regard to possibility

of character occurrence in text:

[0..9] for integers, [0..9,- , .] for

decimals and complete alpha-

bet for text variables (including

Czech characters).

Confirm your selection by

4

key to finish editing.

A status message will be dis-

played. If your password is not

accepted, program returns to

editing mode. If correct pass-

word was entered, you will get

to main menu.

Use

3

to move in menu. This

key moves the lower line item to

upper line. In all menus, the

upper line with blinking first

character is always the active

line.

Press

4

to enter in submenu

or to edit item. Pressing

2

in submenu brings you always

back to previous menu

(“Escape” function). If you are in

main menu, pressing of this key

will offer exit from programming

mode.

Menu legend

Some menu items can be

used only for viewing and do

not allow change of values.

Fig. Movement in menu

Fig. Status message

+ Noise f ilter

+ Dynamic f ilter

» En te r p a s s w o r d

○

125 mA

●

250 mA

¤ Pr o d u c tio n d a te

3

key changes character at

cursor position. When the last

available character is reached,

Fig. Read only

Fig. Enter value

Press

4

to return to previous

menu.

Other menu items can be

used to enter value directly.

When you enter the value and

press

4

, a status message will

be displayed.

If the value entered is ac-

cepted, press any key to return

to previous menu or to edit next

item.

If the value entered is out of

range, an error message will be

displayed; press any key to edit

the value.

In some cases, one of listed

values has to be selected.

Fig. Selection of one value

Use

3

to select required item.

When the required value is in

the upper line, press

4

to con-

firm your selection. A status

message will be displayed to

confirm that your selection has

been accepted. Press any key

to return to previous menu or to

edit next item.

In some cases, more of listed

values can be selected.

Fig. Selection of more items

There is a sign “+” (indicating

that the item is selected) or “-

“ (indicating that the item is not

selected) before each of items.

Fig. Selection of more items

Press

2

to change selection

for the item displayed in the

upper line. Press

4

to finish

your selection. A status mes-

sage will be displayed to con-

firm that your selection has

been accepted. Press any key

to return to previous menu.