FLIR

LEPTON® Engineering Datasheet

The information contained herein does not contain technology as defined by the EAR, 15 CFR 772, is publicly available,

and therefore, not subject to EAR. NSR (6/14/2018).

Information on this page is subject to change without notice.

Lepton Engineering Datasheet, Document Number: 500-0659-00-09 Rev: 203

68

6.2

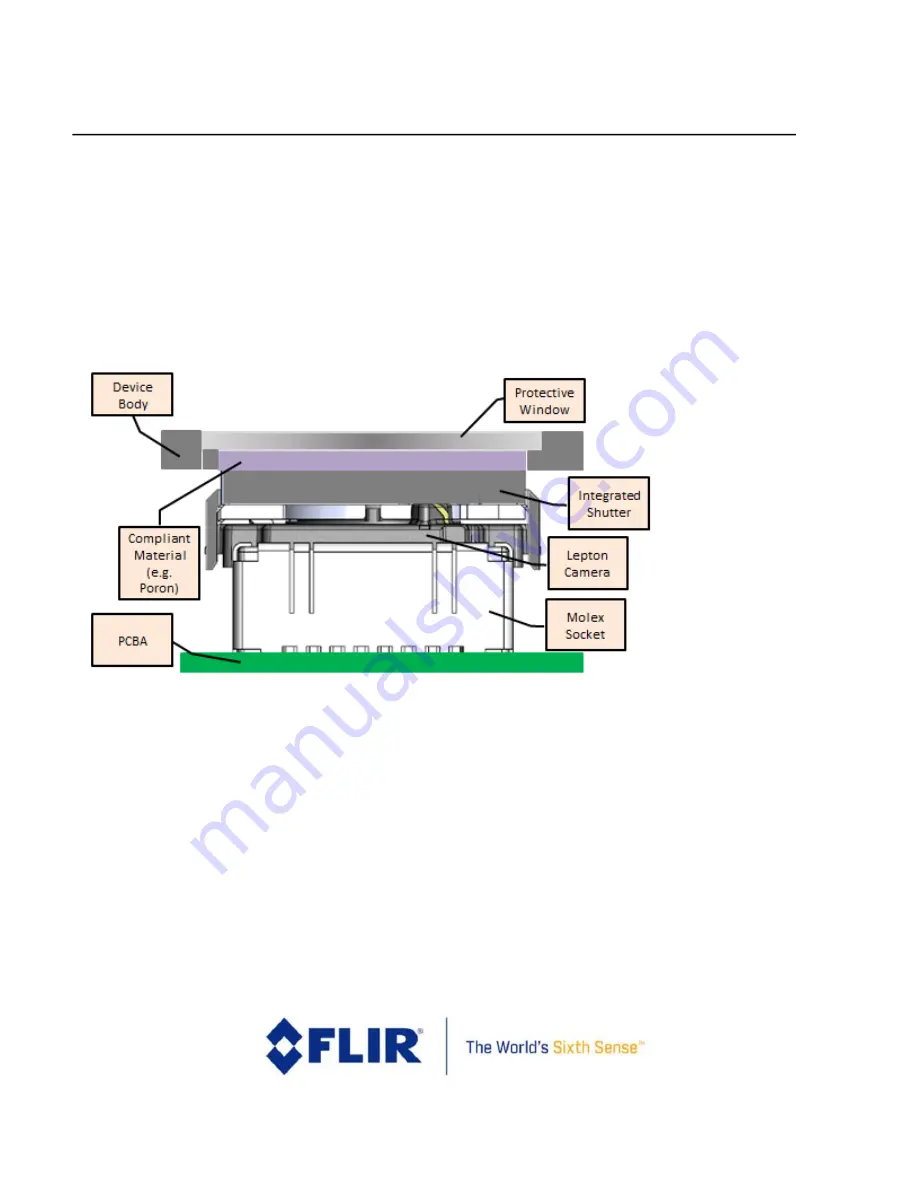

Mechanical Considerations

The socket described in

is not intended to retain the Lepton assembly under

high-shock conditions. It is recommended to incorporate front-side retention such as illustrated in

. Note

that a maximum, uniform, load of 1kgF can be applied to the shutter face without causing failures in shutter

actuation. When designing the foam thickness and compression the tolerances have to be such that the

maximum force of 1kgF at the same time as enough force is exerted to keep the Lepton in the socket.

Figure 46 - Recommended Approach to Retaining Lepton in the end Application

The Lepton camera is not a sealed assembly. Consequently, for most applications it is recommended to locate the

assembly behind a sealed protective window. Common materials for LWIR windows include silicon, germanium,

and zinc selenide (LWIR absorption in silicon is on the order of 15%/mm, which means NEDT is adversely affected

using a silicon window. Bulk absorption in germanium and zinc selenide is negligible, and performance is

essentially unchanged provided both surfaces of the window are anti-reflection (AR) coated.) Note that the

window should be sized large enough to avoid encroaching upon the optical keep-out zone (see