Lit. No. 94196/94197/94198, Rev. 05

17

November 1, 2010

two or more people are recommended. Move

spreader rearward until it balances at the rear of

the bed. Carefully lower the back of the spreader

to the ground so it is resting on its feet.

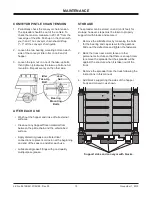

6. Tip the spreader up onto spacers at least 2" tall,

so it is fully supported by the feet.

7.

Do not leave an unsecured spreader standing

on its feet.

After pulling the truck away, either

lower the spreader so it is resting on its 6 legs or

properly support it with blocks and secure it as

directed in the Storage Section. If lowering the

spreader onto its 6 legs, place spacers under the

legs so the feet at the rear of the spreader are off

the ground.

Spacers

Spacers

Feet

REMOVING THE SPREADER

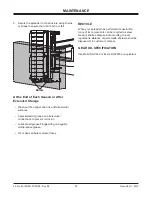

1. The spreader can be removed from the truck bed

either by lifting the spreader by the four molded-in

handles located on the corner legs or by sliding

the spreader out of the truck bed onto the ground.

2. To remove the spreader from the truck without

a lifting device,

fi

rst make sure all material has

been removed from the spreader and the chute is

detached. To empty the spreader and remove the

chute:

a. Remove the two pins that hold the chute to the

hopper body.

b. Disconnect the spinner motor connector.

c. Grasp the chute, raise it and remove it from

the hopper body.

d. Operate the hopper to convey all material from

the spreader.

e. Remove the sill de

fl

ectors by loosening the

bolts for the bearing and gearbox. Slide out

the de

fl

ectors and tighten bolts.

3. Disconnect the electrical connections at the

spreader.

4. Remove any means used to attach the spreader

to the truck bed and ensure the lids are closed

securely.

5. To remove the spreader without a lifting device,

Disconnect

Harness

Remove

Pin

Remove

Pin

CAUTION

Before lifting, verify hopper is empty of

material. The lifting device must be able to

support the spreader's weight.