FISCHER Mess- und Regeltechnik GmbH

Assembly | 3

BA_EN_DS13

7

3 Assembly

3.1 General

The device is designed for wall mounting.

NOTICE! At the factory, the device is calibrated for vertical installation and

only this installation position is allowed.

To ensure safety during installation and maintenance, we recommend installing

a suitable shut-off valve on the system (see accessories). A shut-off valve offers

the following advantages:

• The device can be depressurized or decommissioned.

• The device can be disconnected from the power supply within the applic-

able system for repairs or inspections.

• A function test of the device can be performed on-site.

3.2 Process connection

• By authorized and qualified specialized personnel only.

• The pipes need to be depressurized when the instrument is being connec-

ted.

• Appropriate steps must be taken to protect the device from pressure surges.

• Check that the device is suitable for the medium being measured.

• Maximum pressures must be observed (cf. Tech. data)

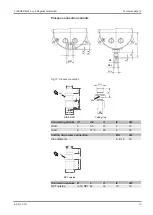

The pressure connections are marked with (+) and (-) symbols on the device.

When the differential pressure is measured, the higher pressure is connected to

the (+) side and the lower pressure to the (-) side.

+

Fig. 5:

Process connection

The pressure lines must be kept as short as possible and installed without any

tight bends to avoid delays.

The pressure lines must be installed at an inclination so that when fluids are

measured no air pockets are created or when measuring gases, no water pock-

ets are created. If the required inclination is not reached, water or air filters must

be installed at suitable places.

In the case of fluid measuring media, the pressure lines must be vented be-

cause different fluid columns in the lines will distort the measurements.

If water is used as a measuring medium, the unit must be protected against

frost.

Pulsating pressure on the system side can lead to wear and functional prob-

lems. To safeguard this, we recommend installing absorption elements in the

pressure line.