C1 Controllers and Transmitters

Instruction Manual

September 2009

6

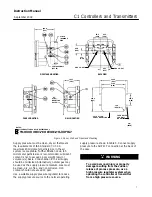

Panel Mounting

Cut a hole in the panel surface according to the

dimensions shown in figure 2. Remove the cap

screws (key 252), brackets (key 251), and vent

assembly (key 28). Slide the controller or transmitter

into the cutout and reattach the brackets. Tighten the

cap screw located in the center of each bracket to

draw the case snugly and evenly against the panel.

Reinstall the vent unless a remote vent will be used.

Wall Mounting

Drill four holes in the wall using the dimensions

shown in figure 2. In the bracket (key 251) are 8.7

mm (0.3438 inch) diameter holes. Back out the cap

screw located in the center of each bracket. (The

screws are used for panel mounting but are not

required for wall mounting.) If tubing runs through

the wall, drill holes in the wall to accommodate the

tubings. Figure 2 shows the pressure connection

locations in the back of the case.

Mount the controller to the bracket using the four cap

screws (key 252) provided. Attach the bracket to the

wall, using suitable screws or bolts.

Pipestand Mounting

Use a hammer and punch to knock out the blanks in

the two holes indicated in the back view of figure 2.

Attach the spacer spools (key 228) and the mounting

plate (key 213) to the controller with cap screws,

lock washers, and nuts (keys 215, 221, and 216).

Attach the controller to a 2

−

inch (nominal) pipe with

pipe clamps (key 250).

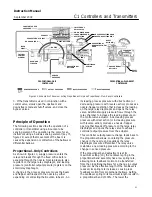

Actuator Mounting

Controllers specified for mounting on a control valve

actuator are mounted at the factory. If the instrument

is ordered separately for installation on a control

valve actuator, mount the instrument according to

the following instructions.

Mounting parts for the different actuator types and

sizes vary. Two typical actuator

−

mounting

installations are shown in figure 3; see the parts list

for parts required for the specific actuator type and

size involved.

Use a hammer and punch to knock out the blanks in

the two holes indicated in the back view of figure 2.

Attach the spacer spools (key 228) and the mounting

plate (key 213) to the controller with machine

screws, lock washers, and nuts (keys 215, 221, and

216).

Attach the mounting bracket to the actuator yoke

with cap screws (key 222) and, if needed, spacer

spools. On some designs, the mounting bracket is

attached to the actuator diaphragm casing rather

than to the yoke.

Pressure Connections

WARNING

To avoid personal injury or property

damage resulting from the sudden

release of pressure, do not install any

system component where service

conditions could exceed the limits

given in this manual. Use

pressure

−

relieving devices as required

by government or accepted industry

codes and good engineering practices.

All pressure connections on C1 Series instruments

are 1/4 NPT internal. Use 6 mm (1/4

−

inch) or 10 mm

(3/8

−

inch) pipe or tubing for supply and output

piping. The pressure connection locations are shown

in figure 2.

Supply Pressure

WARNING

Severe personal injury or property

damage may occur from an

uncontrolled process if the instrument

supply medium is not clean, dry,

oil

−

free and noncorrosive. While use

and regular maintenance of a filter that

removes particles larger than 40

micrometers in diameter will suffice in

most applications, check with an

Emerson Process Management field

office and industry instrument supply

medium quality standards for use with

hazardous gas or if you are unsure

about the proper amount or method of

air filtration or filter maintenance.