C1 Controllers and Transmitters

Instruction Manual

September 2009

24

preventative measures are not taken.

Preventative measures may include,

but are not limited to, one or more of

the following; Remote venting of the

unit, re

−

evaluating the hazardous area

classification, ensuring adequate

ventilation, and the removal of any

ignition sources. For information on

remote venting of this controller/

transmitter, refer to page 8.

D

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

Replacing Gauges

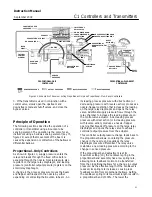

Refer to figures 21 and 22 for key number locations

unless otherwise directed.

Three gauge configurations are available for C1

units.

D

Output and supply pressure indications

D

Output and process pressure indications

D

Output, process, and supply pressure

indications

One gauge type (key 2) is used for both output and

supply pressure indications when the gauges are

installed inside the controller case. Key 2 features a

1/8

−

inch connecting stem that matches the threaded

gauge boss extending from the relay base.

In some cases, a process pressure gauge (key 4)

covers the position of the internal supply pressure

gauge. The supply pressure gauge has been

removed and replaced with a pipe plug (key 15). The

pressure control block (key 10) is different to

accommodate a different control tubing assembly

(key 23) with a pressure connection (key 14) for a

process pressure gauge. If a supply pressure gauge

is required, a gauge with a 1/4

−

inch connecting stem

(key 3) must be mounted on the supply pressure

regulator.

CAUTION

Before performing this procedure, be

sure the replacement gauges are the

correct range so they are not damaged

by overpressure.

Note

Key 2 is used as both a supply gauge

and an output gauge on units without

a process pressure gauge. A quantity

of 2 is required for these units. On

units with a process pressure indicator

gauge (key 4), key 2 is used for the

output gauge. A quantity of 1 is

required for these units.

Use key 3 for supply pressure

indication when a process pressure

gauge is installed. Key 3 installs on the

supply pressure regulator.

1. Shut off the supply pressure and process lines to

the controller or transmitter.

2. Remove the gauge to be replaced:

D

Unscrew the output or supply gauge (key 2)

from the relay base.

D

Unscrew the process pressure gauge (key 4)

from the process connection (key 14).

D

Unscrew the supply gauge (key 3) from the

supply pressure regulator.

3. Coat the threads of the replacement gauge with a

sealant.

4. Screw the replacement gauge into the relay base,

process connection, or supply pressure regulator.

5. Check for leaks by applying the correct supply

pressure with the nozzle capped to produce full

output pressure.

Replacing Bourdon Tube

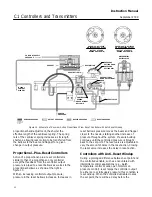

Refer to figure 23 for key number locations unless

otherwise directed.

1. Shut off the supply pressure and process lines to

the controller or transmitter.

2. Unscrew the machine screw (key 56) to

disconnect the link (key 16) and bearing (key 31)

from the beam (key 39). Be careful to avoid losing

the bearing (key 31). Washer(s) (key 62) for the

machine screw (key 56) are at times furnished for

insertion at the beam (key 39) connection to ensure

alignment of the connecting link (key 16).