167D Series

7

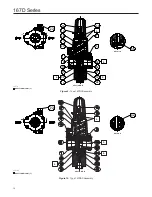

4. Place the diaphragm assembly (key 16) on the body

(key 1) as shown in Figures 7 through 10. Push down

on the diaphragm assembly to make sure the valve

plug (key 57) strokes smoothly and approximately

1/16-inch / 1,6 mm.

Note

In step 5, if installing a control spring of

a different range, be sure to delete the

spring range originally appearing on the

label and indicate the new spring range.

5. Stack the control spring (key 17) and upper spring

seat (key 20) onto the diaphragm assembly (key 16).

6. Install the spring case assembly (key 7) on the body

(key 1) with the vent oriented to prevent clogging or

entrance of moisture. Install the six fl ange

screws (key 3) using a crisscross pattern and torque

to 15 to 30-inch-pounds / 1,7 to 3,4 N•m.

Note

On Types 167DS and 167DAS, lubricate

the adjusting screw (key 18) thread to

reduce galling of the stainless steel.

7. When all maintenance is complete, refer to

the Startup and Adjustment section to put the

switching valve back into operation and adjust

the pressure setting. Tighten the hexnut (key 19)

if used, and install the closing cap (key 33) if used.

!

WARNING

To avoid personal injury, property damage,

or equipment damage caused by sudden

release of pressure or explosion of

accumulated gas, do not attempt any

maintenance or disassembly without fi rst

isolating the switching valve from system

pressure and relieving all internal pressure

from the switching valve.

Trim Maintenance

Key numbers are referenced in Figures 7 through 10.

1. Unscrew the spring retainer (key 48) and separate

the spring retainer and O-ring (key 14) from the

body (key 1).

2. Inspect the removed parts for damage and debris.

Replace any damaged parts. Apply a high

quality lubricant to the O-ring (key 50)

before reassembling.

3. To remove the valve stem (key 11) and valve plug

(key 57), grasp the end and pull it straight

out of the body (key 1). Inspect the parts for

damage and debris. Replace any damaged parts.

The valve stem and valve plug may be cleaned or

replaced. Types 167D and 167DS: If the soft seat

(key 15) was removed, make sure it is properly

snapped into place before installing the valve

stem. Apply a high quality lubricant to the O-ring

(key 50) before reinstalling the valve stem.

4. Install valve stem and valve plug by sliding the

valve stem through center of the seat (key 58)

until the valve plug contacts the seat. Apply

lubricant to O-ring (key 14) and thread in spring

retainer (key 48). Torque spring retainer to

18 to 22 foot-pounds / 24 to 30 N•m.

Diaphragm Maintenance

Key numbers are referenced in Figures 7, 8, 9, 10,

and 12.

1. Back out the adjusting screw or handwheel (key 18)

until compression is removed from the spring (key 17).

2. Remove the fl ange screws (key 3) to separate

the spring case assembly (key 7) from the body

(key 1). Remove the upper spring seat (key 20)

and the control spring (key 17).

3. Remove the diaphragm assembly (key 16),

inspect the diaphragm, and replace the assembly,

if necessary.

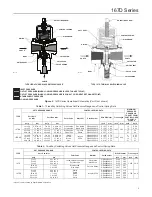

Figure 6.

167D Series Spring Case Vent Positions

POSITION 1 (ALIGNED WITH INLET) (STANDARD)

POSITION 3

POSITION 4

POSITION 2

GE31784