167D Series

4

Product Description

The 167D Series switching valves are pneumatically

operated and controlled units, built with a wide range of

capabilities to handle those switching applications that

involve venting, on-off control, and failure modes.

• The Types 167D and 167DS are two-way

switching valves.

• The Types 167DA and 167DAS are three-way

switching valves.

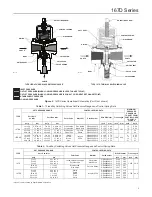

Principle of Operation

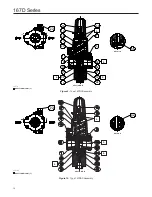

Refer to Figure 2 and also refer to Figures 3 through

5 for port D location. Control pressure enters the

switching valve through port D (not shown in Figure 2)

and registers under the diaphragm. Control pressure

overcomes the spring force and the diaphragm and

raise the valve plug, closing port C and opening port B

of the Type 167DA three-way switching valve. In this

condition, the Type 167D construction is turned off and

the Type 167DA construction provides flow from path

A to B. If, either intentionally or through pneumatic

failure, the control pressure drops below the spring

force, the diaphragm and valve plug move downward,

opening port C and closing port B of the Type 167DA

three-way switching valve. In this condition both

constructions provide a flow path from port A to

port C. The pressure change necessary to switch the

valve depends on the spring used and the setting of

the adjusting screw on the switching valve.

Overpressure Protection

The 167D Series switching valves have maximum

outlet pressure ratings that are lower than their

maximum inlet pressure ratings. A pressure-

relieving or pressure-limiting device is needed if inlet

pressure can exceed the maximum outlet pressure

rating. Overpressuring any portion of a switching

valve or associated equipment may cause leakage,

parts damage, or personal injury due to bursting of

pressure-containing parts or explosion of accumulated

gas. Switching valve operation within ratings does

not preclude the possibility of damage from external

sources or from debris in the pipeline. A switching

valve should be inspected for damage periodically and

after any overpressure condition.

Installation

Note

If the switching valve is shipped

mounted on another unit, install that

unit according to the appropriate

Instruction Manual.

!

WARNING

Personal injury, property damage,

equipment damage, or leakage due to

escaping gas or bursting of pressure-

containing parts may result if this

switching valve is overpressured or

is installed where service conditions

could exceed the limits given in the

Specifications section, or where

conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage,

provide pressure-relieving or pressure-

limiting devices (as required by the

appropriate code, regulation, or

standard) to prevent service conditions

from exceeding those limits.

Before installing a Type 167D, 167DA, 167DS, or

167DAS switching valve, be sure the installation

complies with the following installation guidelines:

1. Switching valve operation within ratings does not

preclude the possibility of damage from debris in

Table 3.

Flow and Sizing Coefficients

TYPES

BODY SIZE

PORT

WIDE-OPEN FLOW COEFFICIENTS

C

1

IEC SIZING

COEFFICIENTS

C

g

C

v

X

t

167D, 167DS

1/4 NPT

C

41.46

1.09

37.56

0.89

1/2 NPT

46.50

1.18

39.03

0.96

167DA, 167DAS

All sizes

B

27.79

0.96

28.74

0.52

1/4 NPT

C

49.35

1.60

30.58

0.59

1/2 NPT

58.86

1.81

32.22

0.66