167D Series

2

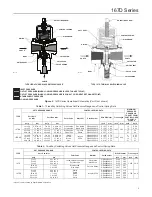

Specifications

Some general 167D Series switching valve ratings and other specifications are given on this page. A label on the

spring case gives the control spring range for a given valve as it comes from the factory.

Available Configurations

Types 167D and 167DS:

Two-way switching valve

Types 167DA and 167DAS:

Three-way

switching valves

Body Size, Inlet and Outlet Connection Style

Ports A and C:

1/4 or 1/2 NPT

Vent and Control Pressure Connections

(Port D) and Port B:

1/4 NPT

Maximum Operating Inlet Pressure

(1)

Types 167D and 167DS:

400 psig / 27,6 bar

Types 167DA and 167DAS:

125 psig / 8,6 bar

Types 167DA and 167DAS (NACE):

100 psig / 6,9 bar

Set Pressure Ranges

See Tables 1 and 2

Maximum Diaphragm Pressure

(1)

150 psi / 10,3 bar over outlet pressure setting up

to a maximum of 250 psi / 17,2 bar

Flow and Sizing Coefficients

See Table 3

Spring Case Vent Location

Aligned with inlet

(standard)

, other positions optional

Temperature Capabilities

(1)

Nitrile (NBR)

Standard Service (Types 167D and 167DA only):

-20° to 180°F / -29° to 82°C

Low Temperature Service (Types 167D and

167DA only) and Standard Service (Types 167DS

and 167DAS only):

-40° to 180°F / -40° to 82°C

Fluorocarbon (FKM)

High Temperature Service:

0° to 300°F /

-18° to 149°C

Approximate Weights

Types 167D and 167DA:

1.2 pounds / 0,5 kg

Types 167DS and 167DAS:

2.8 pounds / 1 kg

Options

Types 167D and 167DA

•

Handwheel adjusting screw

• Fluorocarbon (FKM) diaphragm, soft seat, seat,

and O-rings

•

Stainless steel valve stem and plug. Includes

stainless steel seat

•

1-hole panel mount with handwheel adjusting

screw and 1/4 NPT tap spring case

• 3-hole panel mount bonnet with handwheel

adjusting screw and 1/4 NPT spring case

•

1/4 NPT tapped vent spring case

•

1/4 NPT tapped vent and closing cap

• Adjusting screw with locknut and a lock wire to

one flange bolt (For Type 167D only)

• Panel mounting bracket. Includes 1/4 NPT

spring case, standard adjusting screw, nut,

and bracket

• Yoke mounting bracket. Includes 1/4 NPT

spring case, standard adjusting screw, nut,

fasteners, and bracket

• Size 30-70 casing mounting bracket. Includes

1/4 NPT spring case, standard adjusting screw,

nut, fasteners, and bracket

• NACE MR0175 or NACE MR0103 construction

(2)

Types 167DS and 167DAS

•

Handwheel adjusting screw

• Fluorocarbon (FKM) diaphragm, soft seat, seat,

and O-rings

•

1-hole panel mount with handwheel adjusting

screw and 1/4 NPT tap spring case

• Panel mounting bracket. Includes 1/4 NPT

spring case, standard adjusting screw, nut, and

bracket

• Yoke mounting bracket. Includes 1/4 NPT

spring case, standard adjusting screw, nut,

fasteners,

and bracket

• Size 30-70 casing mounting bracket. Includes

nut, fasteners, and bracket

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Product complies with the material requirements of NACE MR0175 or MR0103. Environmental limits may apply.