Design CV500

12

feeler gage to measure between the parts as shown in

figures 11 and 12, making certain the necessary

clearance exists. Compare the measured gap to the

clearance in table 5; proceed as follows:

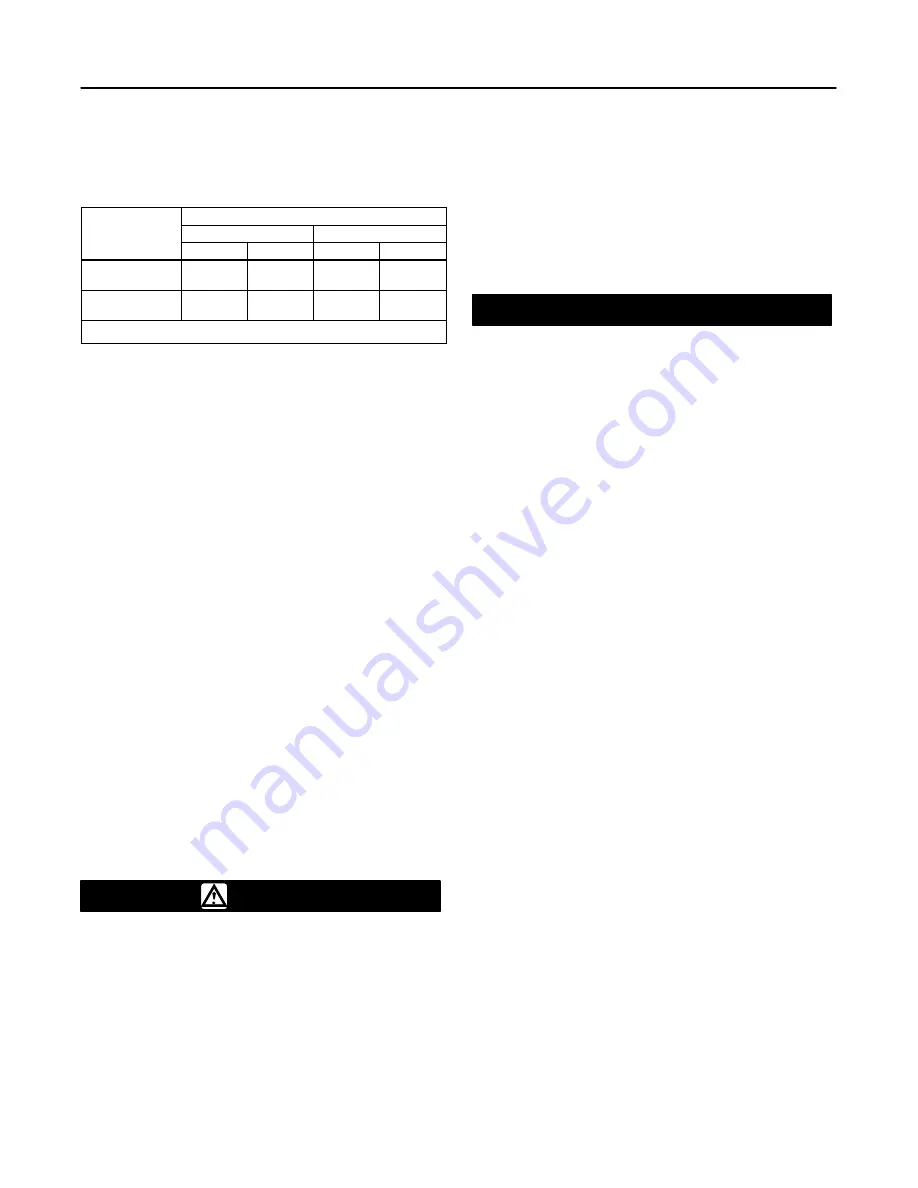

Table 5. Assembly Clearance

PROCESS

SEAT RING AND RETAINER CLEARANCE

PROCESS

TEMPERATURE

mm

Inches

TEMPERATURE

Minimum

Maximum

Minimum

Maximum

To 260

_

C

(500

_

F)

(1)

0.08

0.30

0.003

0.012

Over 260

_

C

(500

_

F)

(2)

0.20

0.30

0.008

0.012

1. Standard Trim

2. Special High Temperature Trim

D

If the measured clearance is within table values,

proceed to the next step.

D

If the measured gap is larger than the maximum,

tighten the retainer—apply more torque than that listed

in figure 7, if necessary, until the clearance is within

maximum and minimum values.

D

If the measured clearance is smaller than the

minimum, remove the retainer, seat ring, and face

seals, clean the parts, and reassemble so as to obtain

the necessary minimum clearance.

10. Perform the Adjusting Actuator Travel procedure

and then install the control valve in the pipeline.

Replacing Ball, Shaft, and Bearings

Perform this procedure to replace the ball (key 2),

expansion pin (key 9), taper pin (key 10), drive shaft

(key 3), follower shaft (key 38), groove pins (key 39),

or bearings (keys 6 and 42). These parts are

independently replaceable; for example, installing a

new ball does not require replacing a reusable valve

shaft or expansion pin assembly. Key numbers refer to

figure 11 for 3 through 8-inch sizes and to figure 12 for

10 and 12-inch sizes unless otherwise indicated.

Disassembly

WARNING

To avoid personal injury resulting from

contact with edges of the V-notch ball

(key 2) and seat ring (key 4) during ball

rotation, stay clear of its edges when

rotating the ball. To avoid damage to

tools, valve parts, or other items

resulting from V-notch ball rotation,

keep tools and other property away from

the edges of the ball.

When the actuator is removed from the

valve, the ball/shaft assembly may

suddenly rotate, resulting in personal

injury or property damage. To avoid

injury or damage, carefully rotate the

ball/shaft assembly to a stable position

in the valve body after the actuator is

disconnected.

CAUTION

To avoid increased leakage, increased

valve component wear or possible

damage to the valve body (key 1), ball

(key 2), drive shaft (key 3), follower shaft

(key 38), and bearings (keys 6 and 42)

resulting from a sharp blow to the

actuator or valve parts, use a wheel

puller to separate the actuator parts

from the valve drive shaft.

Do not drive the actuator parts off the

valve drive shaft since this could move

the valve bearings, shafts, and ball away

from proper alignment, causing

improper seating of the ball. Such

misalignment may result in damage to

valve components if the valve is

returned to service without disassembly

and inspection of the ball alignment.

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve body,

and drain the process media from both sides of the

valve. If using a power actuator, also shut-off all

pressure lines to the power actuator, release all

pressure from the actuator. Use lock-out procedures to

be sure that the above measures stay in effect while

you work on the equipment.

2. Remove the actuator cover. Note the actuator

orientation with respect to the valve body and the lever

orientation with respect to the valve drive shaft (see

figure 3). Remove the lever but do not loosen the

actuator turnbuckle adjustment. Remove the actuator

mounting screws and nuts, and remove the actuator. If

necessary, refer to the actuator instruction manual for

assistance.

3. With the valve body (key 1) out of the pipeline,

loosen the packing nuts (key 16). If the packing is to

be reused, do not remove it. However, Fisher

recommends that the packing be replaced whenever

the drive shaft is removed.

Содержание Design CV500

Страница 26: ...Design CV500 26...

Страница 27: ...Design CV500 27...