REV. 01 2016

21 / 28

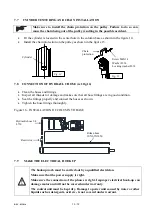

Install the control panel onto the column as shown in the

figure 17.

Check to make sure the motor specification shown in the

nameplate of the motor conforms to the local electric supply.

Make the electric hookup referring to the wiring diagram

(ref. fig.7) using included electric cable. The plug must be

set in compliance with the local regulation in force.

Make sure every component is connected properly.

Make sure the connection of the phases is right and the lift is

grounded.

7.10 ADJUSTMENT OF LIMIT SWITCHES

Only skilled personnel must be allowed to carry out this operation.

An improper adjustment of limit switches could cause damages to the lift, objects

and people.

Limit switches must be adjusted properly during the installation of the lift

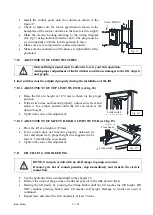

7.10.1 ADJUSTMENT OF TOP LIMIT SWITCH (ref. fig.18)

Raise the lift at a height of

1870 mm

to check for the proper

position.

If the switch does not function properly, unloosen its lever and

adjust it at a proper position until the lift can reach at the

desired height.

Tighten the screw after adjustment.

7.10.2 ADJUSTMENT OF SAFETY HEIGHT LIMIT SWITCH (ref. fig.19)

Place the lift at a height of

200 mm;

If the switch does not function properly, unloosen its

lever and adjust it at a proper height (it is suggested to be

lower 1-3mm than the cross beam).

Tighten the screw after adjustment.

7.11 OIL FILLING AND BLEEDING

DO NOT run power unit with no oil. Damage to pump can occur.

If motor gets hot or sounds peculiar, stop immediately and recheck the electric

connection.

Use the hydraulic fluid recommended in the chapter 5.5.

Remove the oil level plug on the oil tank and pour oil in the tank about 8 liters.

Raising the lift slowly by pressing the lifting button until the lift reaches the full height. DO

NOT continue pressing button after lift reaches full height. Damage to motor can occur if

continued.

Repeat raise and lower the lift completely at least 3 times.

Screw M6X20

Fig. 17

Limit switch

Fig. 18

Fig. 19

Cross beam

Limit switch