REV. 01 2016

22 / 28

7.12 CHECK BEFORE START-UP

During this procedure, observe all operating components and check for proper

installation and adjustment.

DO NOT attempt to raise vehicle until a thorough operation check has been

completed.

7.12.1 GENERAL CHECKS

Make sure all pins and bolts to insure proper mounting.

Make sure the chain for proper installation.

Make sure the electrical system feeding voltage is equal to that specified in the nameplate on

the motor, the electric system connection in conformity of the electric plan shown as the

electric diagram (fig. 6) and for proper grounding.

Make sure the lift is connected to the ground.

Particularly, below checks must be followed:

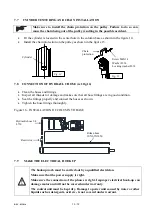

7.12.2

MECHANICAL SAFETIES FOR PROPER INSTALLATION

Check to make sure that safeties will properly engage by pushing the locking button and can be

released properly but pushing the lowering button.

When raising the carriages, listen to the safety hook fall into the safety rack. If not, check the

cause if necessary.

7.12.3

HYDRAULIC SYSTEM FOR PROPER OPERATION

Proper oil level in the tank, refill if needed.

Raise the carriage to the full height and keep the motor running for 5 seconds.

Check all hoses connections to make sure no leakage. Tighten the connections or reseal if

necessary.

Check the carriage for reaching its maximum height.

Repeat the air bleeding of cylinders if necessary.

7.12.4

LIMIT SWITCH FOR PROPER OPERATION

Check to make sure the top limit switch for proper operation. Verify that the power unit stops

working when the carriages reaches the maximum height.

Check to make sure the safety height limit switch for proper operation. Verify the power unit

stops working when the carriage is lowered at about 200mm high.

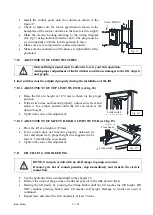

7.13 ANCHORING COLUMNS

If the lift is chosen to be anchored to floor, the concrete slab should have the

compression strength of at least 3000 PSI and the minimum thickness 160mm

with an extension of at least 1.5m from anchoring point.

The anchor bolts can be ordered from the manufacturer.

Using the base plate as guide, drill each hole in the concrete approximately 160mm deep with

the rotary hammer drill D.20. To assure full holding power, do not ream the hole or allow drill

to wobble.