Page 9

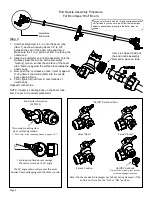

The suction line of your sprayer should contain a ‘siphon tube’ or intake tube which should be rotated so that it just touches the

bottom of the tank surface. (see Detail Views). Reach in and rotate it, as needed, if not already in this position.

A shut-off valve is threaded onto the pipe nipple at the intake location on the tank. It is at this location so you can shut off the flow

of solution to access your system’s screen for cleaning.

Checking/Cleaning the sprayer’s filter/screen:

Start your pump and before it shuts off, reach down and shut the valve to the ‘Closed’ position (lever is perpendicular

to the flow of fluid), then shut off your pump.

Unscrew the knurled nut from the shut-off valve, leaving the valve connected to the tank.

Swing (swivel) the intake assembly towards you. Look in the nut you JUST unscrewed. There is a screen/washer there.

Remove the screen and clean as necessary. Replace when done and reassemble the entire assembly.

Make sure the valve is turned to the ‘Open’ position before restarting your pump.

‘Cut’ View of a ‘Typical’ Tank

(looking inside)

Intake/Siphon Tube/Screen Detail of a Typical L&G/ATV Sprayer (not including the ‘EC’Units)

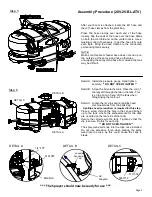

Cleaning the Check Valve

:

If you’re experiencing little to no pressure or the pump is not priming and you’ve checked your filter

screen and it’s clean, and you’ve gone through the other trouble shooting tips, you may need to

clean the check valve.

Remove the head of the pump, which is held on by 7 screws.

The first piece inside the head of the pump is called a check valve, it’s the part responsible for building up pressure

and pumping water/solution through the lines.

Clean the check valve under hot, soapy water (such as a good grade dish soap).

Give it a very light scrubbing with something like an old toothbrush, something with soft bristles.

Then let it soak for about an hour or so in the hot soapy solution and replace in the pump and reassemble the pump.

Most times this will restore most, if not all of the prime of a pump.

If you’re still having issues with pressure after this step, it would be recommended to replace this part.

Checking the Pressure Switch

:

If your motor is not running and you’ve checked the following: for loose wiring connections, fuse, and made sure

you were connected to a fully charged battery and everything is fine, but the motor won’t run, then it’s time to

check to see if the pressure switch is bad.

Remove the cover off the 1” square box (pressure switch) on the head of the pump, the cover is held on by

one phillips-head screw. This will expose the two red wires.

With the pump connected to a good 12 volt power source and everything on.

Slip the two red wires off the terminals and touch them together.

If the motor runs, it means the pressure switch is bad and needs to be replaced.

Warning:

It is NOT recommended to run the pump this way, as the pump will continue to run and not shut off.

This could result in blown hoses when all discharges are closed.

Also, this could result in premature failure of the pump completely.