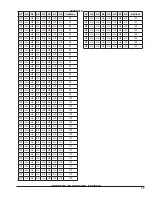

22

Point Name

BACnet Data Type

BACnet Object Id N2 Data Type N2 Point Address

Lon Name

Lon SNVT Type

Boiler2

Error History 2

AI

61

AI

61

nvoFl1ErHt2_XXX

SNVT_count_f

Boiler2

Error History 3

AI

62

AI

62

nvoFl1ErHt3_XXX

SNVT_count_f

Boiler2

Error History 4

AI

63

AI

63

nvoFl1ErHt4_XXX

SNVT_count_f

Boiler2

Error

History 5

AI

64

AI

64

nvoFl1ErHt5_XXX

SNVT_count_f

Boiler2

Error History 6

AI

65

AI

65

nvoFl1ErHt6_XXX

SNVT_count_f

Boiler2

Error History 7

AI

66

AI

66

nvoFl1ErHt7_XXX

SNVT_count_f

Boiler2

Error History 8

AI

67

AI

67

nvoFl1ErHt8_XXX

SNVT_count_f

Boiler2

Error History 9

AI

68

AI

68

nvoFl1ErHt9_XXX

SNVT_count_f

Boiler2

Error History 10

AI

69

AI

69

nvoFl1ErHt10_XXX

SNVT_count_f

Boiler2

Error History 11

AI

70

AI

70

nvoFl1ErHt11_XXX

SNVT_count_f

Boiler2

Error History 12

AI

71

AI

71

nvoFl1ErHt12_XXX

SNVT_count_f

Boiler2

Error History 13

AI

72

AI

72

nvoFl1ErHt13_XXX

SNVT_count_f

Boiler2

Error History 14

AI

73

AI

73

nvoFl1ErHt14_XXX

SNVT_count_f

Boiler2

Error History 15

AI

74

AI

74

nvoFl1ErHt15_XXX

SNVT_count_f

Boiler

3

detected

BI

75

DI

75

nvoFl2Detct_XXX

SNVT_switch

Boiler

3

Outlet temperature

AI

76

AI

76

nvoFl2OutTmp_XXX

SNVT_temp_p

Boiler

3

Inlet temperature

AI

77

AI

77

nvoFl2InTmp_XXX

SNVT_temp_p

Boiler

3

Vent temperature

AI

78

AI

78

nvoFl2VntTmp_XXX

SNVT_temp_p

Boiler

3

High Limit temperature

AI

79

AI

79

nvoFl2HiLmTp_XXX

SNVT_temp_p

Boiler

3

Operator temperature

AI

80

AI

80

nvoFl2OpTmp_XXX

SNVT_temp_p

Boiler

3

Mod Rate

AI

81

AI

81

nvoFl2ModRat_XXX

SNVT_lev_percent

Boiler

3

Mix Rate

AI

82

AI

82

nvoFl2MixRat_XXX

SNVT_lev_percent

Boiler

3

Ignition Status

AI

83

AI

83

nvoFl2IgStat_XXX

SNVT_count_f

Boiler

3

Runtime

AI

84

AI

84

nvoFl2Rtm_XXX

SNVT_count_f

Boiler

3

Cycles

AI

85

AI

85

nvoFl2Cyc_XXX

SNVT_count_f

Boiler

3

Pump

AI

86

AI

86

nvoFl2Pmp_XXX

SNVT_count_f

Boiler

3

Pump Runtime

AI

87

AI

87

nvoFl2PmpRtm_XXX

SNVT_count_f

Boiler

3

Error

Code

AI

88

AI

88

nvoFl2ErrCod_XXX

SNVT_count_f

Boiler

3

Error History 1

AI

89

AI

89

nvoFl2ErHt1_XXX

SNVT_count_f

Boiler

3

Error History 2

AI

90

AI

90

nvoFl2ErHt2_XXX

SNVT_count_f

Boiler

3

Error

History 3

AI

91

AI

91

nvoFl2ErHt3_XXX

SNVT_count_f

Boiler

3

Error

History 4

AI

92

AI

92

nvoFl2ErHt4_XXX

SNVT_count_f

Boiler

3

Error History 5

AI

93

AI

93

nvoFl2ErHt5_XXX

SNVT_count_f

Boiler

3

Error History 6

AI

94

AI

94

nvoFl2ErHt6_XXX

SNVT_count_f

Boiler

3

Error History 7

AI

95

AI

95

nvoFl2ErHt7_XXX

SNVT_count_f

Boiler

3

Error History 8

AI

96

AI

96

nvoFl2ErHt8_XXX

SNVT_count_f

Boiler

3

Error History 9

AI

97

AI

97

nvoFl2ErHt9_XXX

SNVT_count_f

Boiler

3

Error History 10

AI

98

AI

98

nvoFl2ErHt10_XXX

SNVT_count_f

Boiler

3

Error History 11

AI

99

AI

99

nvoFl2ErHt11_XXX

SNVT_count_f

Boiler

3

Error History 12

AI

100

AI

100

nvoFl2ErHt12_XXX

SNVT_count_f

Boiler

3

Error History 13

AI

101

AI

101

nvoFl2ErHt13_XXX

SNVT_count_f

Boiler

3

Error History 14

AI

102

AI

102

nvoFl2ErHt14_XXX

SNVT_count_f

Boiler

3

Error History 15

AI

103

AI

103

nvoFl2ErHt15_XXX

SNVT_count_f

Boiler4

detected

BI

104

DI

104

nvoFl3Detct_XXX

SNVT_switch

Boiler4

Outlet temperature

AI

105

AI

105

nvoFl3OutTmp_XXX

SNVT_temp_p

Boiler4

Inlet temperature

AI

106

AI

106

nvoFl3InTmp_XXX

SNVT_temp_p

Boiler4

Vent temperature

AI

107

AI

107

nvoFl3VntTmp_XXX

SNVT_temp_p

Boiler4

High Limit temperature

AI

108

AI

108

nvoFl3HiLmTp_XXX

SNVT_temp_p

Boiler4

Operator temperature

AI

109

AI

109

nvoFl3OpTmp_XXX

SNVT_temp_p

Boiler4

Mod Rate

AI

110

AI

110

nvoFl3ModRat_XXX

SNVT_lev_percent

Boiler4

Mix Rate

AI

111

AI

111

nvoFl3MixRat_XXX

SNVT_lev_percent

Boiler4

Ignition Status

AI

112

AI

112

nvoFl3IgStat_XXX

SNVT_count_f

Boiler4

Runtime

AI

113

AI

113

nvoFl3Rtm_XXX

SNVT_count_f

Boiler4

Cycles

AI

114

AI

114

nvoFl3Cyc_XXX

SNVT_count_f

Boiler4

Pump

AI

115

AI

115

nvoFl3Pmp_XXX

SNVT_count_f

Boiler4

Pump Runtime

AI

116

AI

116

nvoFl3PmpRtm_XXX

SNVT_count_f

Boiler4

Error Code

AI

117

AI

117

nvoFl3ErrCod_XXX

SNVT_count_f

Boiler4

Error History 1

AI

118

AI

118

nvoFl3ErHt1_XXX

SNVT_count_f

Boiler4

Error History 2

AI

119

AI

119

nvoFl3ErHt2_XXX

SNVT_count_f

Boiler4

Error History 3

AI

120

AI

120

nvoFl3ErHt3_XXX

SNVT_count_f

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED